Introduction

Most things people buy today are built to be replaced, not repaired. That’s a problem for your wallet and for the planet. Global e-waste alone reached roughly 62 million metric tons in 2022—a record high that reflects short product lifespans and design choices that discourage repair [1]. At the same time, marketing terms like “heirloom quality” are often vague, warranties are full of exclusions, and “lifetime” can be defined however a brand chooses.

Bravewood exists to change that. We turn craftsmanship claims into measurable standards with the Heirloom Readiness Standard—a test-backed rubric that evaluates materials, construction, repairability, provenance, and the warranty/care ecosystem. We verify maker lineage, run durability tests aligned to recognized methods, and maintain lifetime care pathways so you can buy it once, use it well, and pass it down.

In this guide, you’ll get:

- A practical definition of heirloom products (with checkable criteria)

- A Materials & Methods Field Guide and simple at-home verification tests

- An Anti‑Obsolescence & Lifespan Audit you can run before you buy

- Category playbooks with care schedules and total cost of ownership (TCO) pointers

- The Bravewood Difference: how we operationalize heirloom quality with standards, testing, lineage, and transparency

- Introduction

- Heirloom Products, Defined: What Makes Goods Heirloom Quality

- The Heirloom Readiness Standard: A Cross-Category Scoring Rubric

- Generational Craftsmanship: From Lineage to Measurable Outcomes

- Anti‑Obsolescence and the Lifespan Audit Framework

- Durable Materials and Construction: A Field Guide

- Category Longevity Playbooks + TCO Calculator

- The Bravewood Difference: Durability Protocol and Transparency Ledger

- Care That Preserves Value: Long-Term Maintenance for Heirloom Goods

- FAQs: Heirloom Quality, Warranties, and Longevity

- Conclusion

- Disclaimer

- References

Heirloom Products, Defined: What Makes Goods Heirloom Quality

“Heirloom quality” isn’t a feeling—it’s a standard. An heirloom product pairs:

- Durable materials that are appropriate for the environment and loads

- Enduring construction methods that resist failure and can be serviced

- Repairability by design (fasteners, parts, documentation)

- Provenance and transparency (materials disclosure, traceability, certifications)

- Warranty and care support that enable multi‑decade service

For a quick reality check: nonstick pans commonly last under five years; cast iron can be refurbished and used for generations with proper care [2]. Likewise, furniture built with time‑tested joinery (dovetails, mortise-and-tenon) and solid hardwoods tends to be serviceable for decades, unlike veneered particleboard that fails at joints and edges [3]. Under the hood, credible durability claims align to recognizable test methods and standards families (ASTM, ISO) for abrasion, corrosion, load/impact, and environmental exposure [4][5]. Responsible sourcing and material quality are strengthened through certifications like FSC for wood and Leather Working Group for leather [6][7].

Durable Materials: Woods, Metals, Leather, and Textiles

Choose materials whose properties match the job—and verify the spec, not just the label.

- Woods

- Look for solid hardwoods from durable species. As examples, white oak (~1360 lbf) and hard maple (~1450 lbf) have Janka hardness values that correlate with dent resistance and long-term durability when paired with stable joinery [8].

- Confirm species disclosures; ask about moisture content and grain orientation for structural parts.

- Metals

- Stainless steel: 304 is the general-purpose workhorse; 316 adds molybdenum for improved corrosion resistance in marine/coastal environments. Prefer solid brass over plated hardware for long-term wear and refinishability.

- Corrosion resistance and finish durability can be anchored to recognized test families like salt-spray/fog and abrasion methods from ASTM/ISO [4][5].

- Leather

- Full‑grain leather in the 1.2–2.0 mm+ range (approx. 3–5+ oz) wears in, not out. Verify tannery standards and traceability through Leather Working Group [7].

- Textiles

- For high-use upholstery and luggage, look for abrasion test disclosures. Industry targets often cite 20,000+ Martindale cycles (ISO 12947) for heavy residential use, with higher numbers for commercial contexts [13]. Wyzenbeek (ASTM D4157) is the U.S. oscillatory abrasion analogue; look for clear test method and results [14].

- A material choice example: cast iron cookware is a classic heirloom choice because it can be re‑seasoned indefinitely, while most nonstick coatings degrade and require frequent replacement [2].

Enduring Construction: Joinery, Stitching, and Hardware

Construction tells you how forces move through a product—and where it will fail or hold for decades.

- Furniture joinery

- Heirloom furniture relies on mechanical joints that lock and distribute loads: dovetails for drawer boxes, mortise-and-tenon for frames and legs. These time‑tested methods outlast glue‑and‑staple shortcuts [3].

- Leather goods

- Saddle stitching (two needles, one thread) resists thread failure better than lock stitching for stress points. Typical durability targets are 6–8 stitches per inch (SPI) on thick full‑grain leather; stress areas may use fewer SPI with heavier thread for tear resistance.

- Hardware and fasteners

Repairability and the Service Ecosystem

Heirloom products anticipate care and repair. Hallmarks include:

- Serviceable fasteners and modular components (no permanent adhesives where future service is likely)

- Published parts catalogs with availability windows (e.g., 10+ years)

- Repair guides and documentation (a la iFixit’s repairability model and teardown documentation) [10]

- Reasonable parts pricing and turnaround targets

Without these, even great materials can become disposable.

Provenance and Transparency

Transparency protects buyers—and elevates true makers:

- Public bill of materials (species, grade, thickness, hardware alloys, finish type)

- Traceable sourcing with certifications like FSC for wood and Leather Working Group for leather; OEKO‑TEX STANDARD 100 for textiles where skin contact or chemical exposure matters [6][7][9]

- Serial-numbered traceability that links each product to the inspection log

- Structured data (Product, Brand) to strengthen entity clarity and verify claims across the web [11]

Warranty and Care Support That Actually Delivers

Real “buy it for life” support looks like:

- Clear warranty terms, exclusions, and what counts as normal wear

- Published service metrics (average turnaround time, resolution rates)

- Parts availability windows and a care toolkit with instructions

As context, some brands back specific items with an unconditional guarantee that sets a high bar for consumer trust [12]. Meaningful warranties pair with a robust care ecosystem to ensure a product’s multi‑decade journey.

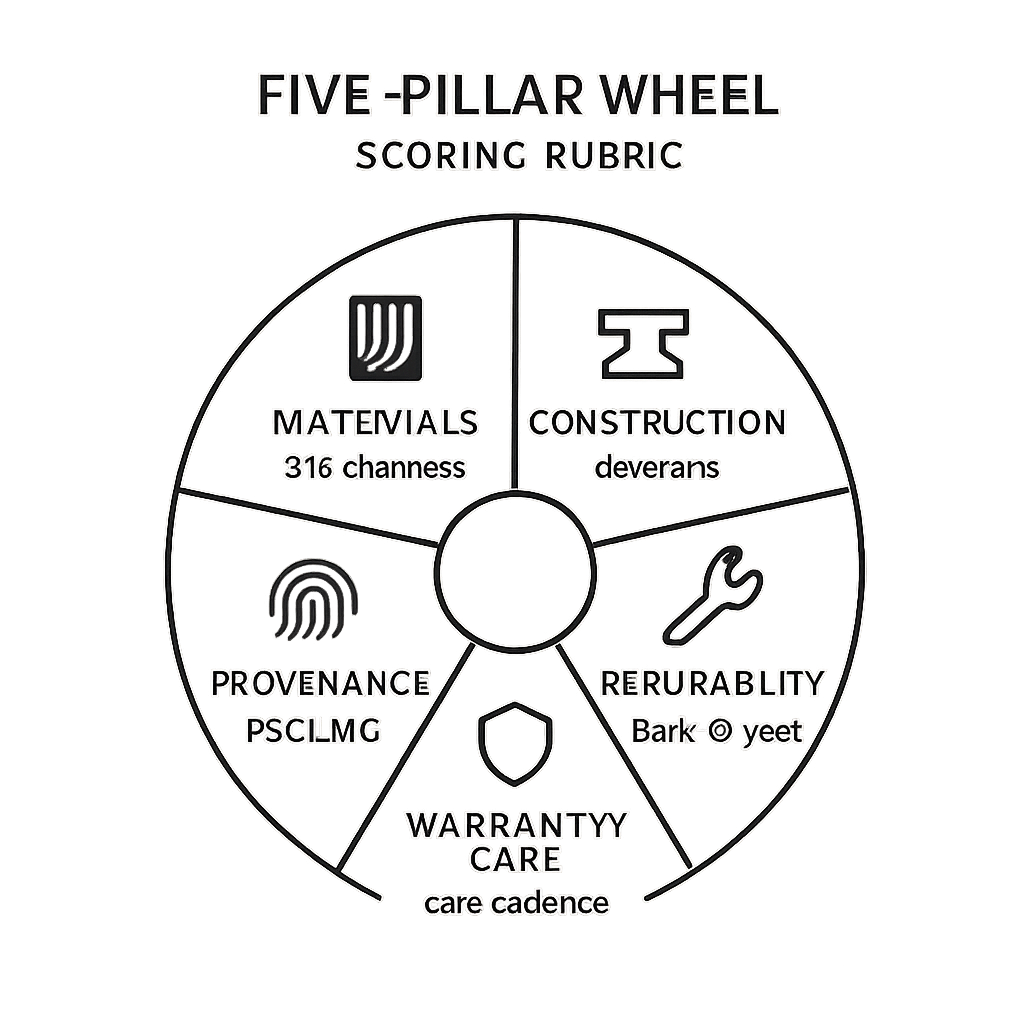

The Heirloom Readiness Standard: A Cross-Category Scoring Rubric

We created the Heirloom Readiness Standard to convert vague claims into measurable scores. It evaluates five pillars—materials, construction, repairability, provenance, and warranty/care—anchored to recognized test families for abrasion, corrosion, mechanical strength, and environmental exposure (ASTM/ISO) [4][5]. Each score is evidence-backed with teardown photos, labeled measurements, and lab summaries where applicable.

The Criteria and Thresholds

Minimum spec thresholds by pillar (illustrative cross‑category guidance):

- Materials

- Woods: solid hardwoods (species disclosed); Janka hardness benchmarks appropriate to use [8]

- Metals: 304/316 stainless, solid brass; finish durability aligned to recognized tests [4][5]

- Leather: full‑grain, 1.2–2.0 mm+ with reputable tannery standards [7]

- Textiles: disclose abrasion tests and method (e.g., ≥20,000 Martindale cycles per ISO 12947 or robust Wyzenbeek results per ASTM D4157) [13][14]

- Construction

- Furniture: dovetails, mortise‑and‑tenon; stress reinforcements documented [3]

- Leather goods: saddle stitching at appropriate SPI with reinforced stress points

- Hardware: serviceable fasteners; replaceable wear components

- Repairability

- Parts catalogs and pricing; availability window of 10+ years for serviceable categories

- Repair guides or service centers with published turnaround targets

- Provenance

- Warranty & Care

- Transparent terms; average days to resolution published; care schedules and tool lists

How to Use the Heirloom Readiness Checklist (In-Store and Online)

Apply the checklist before you buy:

- Ask for the BOM, test summaries (what methods, what thresholds), and certifications (FSC certificate code; LWG-rated tannery) in writing [6][7].

- Inspect construction tells: look for joinery photos on furniture, saddle stitching and backers on leather, and serviceable fasteners.

- Verify textile abrasion claims and the test method (Martindale per ISO 12947 vs Wyzenbeek per ASTM D4157) [13][14].

- Ensure there’s a published parts/repair pathway and realistic warranty terms.

Label Decoding and Spec Verification

- Metals: “18/8” or “18/10” indicates chromium/nickel content in stainless; 304 vs 316 denotes alloy family and corrosion profile. Manufacturers should disclose alloy and finish method (e.g., powder coat) with test references [4][5].

- Leather: “Full‑grain” ≠ “genuine.” Look for thickness in mm or ounces and LWG-rated source [7].

- Textiles: Abrasion numbers must include the method (ISO Martindale vs ASTM Wyzenbeek) to be comparable [13][14].

- Wood: Insist on species, not just “hardwood,” and construction method (solid vs veneer).

At‑Home Field Tests (Magnet, Calipers, Moisture, Finish Inspection)

- Magnet: Check for ferrous content in “stainless” claims (some stainless grades are partially magnetic). This is a clue, not a definitive test.

- Calipers: Measure leather thickness and hardware stock.

- Moisture meter/hygrometer: Validate wood acclimation and plan for humidity ranges.

- Finish/edge inspection: Look for even coverage, deburred edges, and reinforced stress points.

Cross-reference your observations with maker documentation; avoid any destructive or warranty‑voiding tests.

Sample Scores: Heirloom vs. Mass-Market Teardown Comparisons

When we score products, we document:

- Measured thicknesses (leather, hardware, finishes), joinery types, stitch density

- Fastener types (serviceable vs proprietary), modularity, and parts lists

- Lab summaries tied to method designations (e.g., corrosion fog per ASTM family; abrasion via ISO/ASTM) [4][5]

Category examples illustrate why specs matter: cast iron outlasts typical nonstick; robust joinery outlasts glue-and-staple boxes [2][3].

Download the Printable Checklist + Scorecard

Use our printable and mobile-friendly checklist to evaluate products in minutes. Each release is versioned and dated for transparency. Keep your completed scorecards with receipts and care notes to support future warranty or resale.

Generational Craftsmanship: From Lineage to Measurable Outcomes

“Generational craftsmanship” is more than “handmade.” It’s the transfer of skills, standards, and quality systems over time. Cultural frameworks recognize that craft knowledge is built through practice, mentorship, and community transmission [15][16]. Scholarship on skill acquisition underscores how embodied know‑how shortens the path to mastery and improves outcomes [17]. We translate lineage into metrics: tighter tolerances, more consistent stitch density, and lower failure/warranty rates.

What ‘Generational’ Means vs. Artisanal or Handmade

An artisanal, one‑off item can be wonderful—but “generational” implies documented training, repeatable standards, and workshop QA that persists across decades. Craft councils outline how practice, community, and apprenticeship underpin legitimate craft traditions [15].

Apprenticeship and Outcomes: Tolerances, Stitch Consistency, Failure Rates

In workshops with formal apprenticeships and QA checkpoints, you can measure outcomes:

- Joinery gaps held within tight tolerances across batches

- Stitch density variance decreased as training milestones are achieved

- Lower warranty claim rates over time as process controls mature

These data snapshots, anonymized and time-stamped, are strong signals of real generational craft. Industry bodies and councils provide frameworks for apprenticeship and recognition [18].

Techniques that Signal Longevity

Heirloom techniques exist because they work: hand‑cut dovetails resist racking; mortise‑and‑tenon joints distribute loads; saddle stitching survives thread breaks better than lock stitching. Choose methods backed by centuries of service and modern documentation [3].

Verifying Craft Claims: The Craft Lineage Map

Ask makers to publish:

- Maker bios with years in trade and verifiable training histories

- Time‑stamped workshop process media and QA checkpoints

- Serial-number traceability tied to inspection logs and batches

- Structured data for Organization/Brand/Product/Article to strengthen identity clarity and verifiability across platforms [11][16]

Anti‑Obsolescence and the Lifespan Audit Framework

Planned obsolescence takes many forms—contrived durability, systemic (proprietary fasteners/parts), and perceived (style churn). The stakes are real: the world generated ~62 million metric tons of e‑waste in 2022 [1]. Policy is catching up (EU Right to Repair), and consumer tools like iFixit’s repairability scores help buyers make better choices [19][10]. We recommend running a Lifespan Audit before every major purchase.

Planned Obsolescence, Explained

- Contrived durability: components designed to wear prematurely

- Systemic obsolescence: closed ecosystems, proprietary fasteners, no parts

- Perceived obsolescence: frequent style changes and marketing pressure

These concepts are widely documented in reputable explainers and policy discussions [20][19].

Software and Support Windows as Lifespan Drivers

For connected devices, usable life often ends with the last security update. Ask about:

- OS and security patch support timelines

- Battery replacement feasibility and cost

- Availability of service documentation and parts

Where published, repairability indices and teardown evidence offer early signals [10].

Repairability Cues: Fasteners, Modularity, Documentation

Use this pre‑purchase checklist:

- Fasteners: Phillips/Torx/hex over proprietary; avoid permanent adhesives where service is likely

- Modularity: Replaceable batteries, zippers, straps, bushings, feet, gaskets

- Documentation: Public service manuals and parts catalogs (and fair parts pricing)

Repairability scoring and teardown examples illustrate what “serviceable by design” looks like [10].

Policy Landscape and Your Rights

The EU’s Right to Repair initiatives aim to extend product lifetimes by improving access to parts, tools, and documentation, with evolving scope by country and category [19]. Track how new rules may cover your products and what obligations manufacturers have for repair.

Run the Lifespan Audit Before You Buy

- Expected life: Published test thresholds and real‑world service data

- Replaceables: Batteries, zippers, wheels, burners, gaskets—are they available and priced fairly?

- Support windows: Software updates, parts timelines (target 7–10+ years in many categories)

- Total cost: Compare purchase + maintenance + likely repairs vs frequent replacements

Save seller responses; they’re useful for warranty claims later.

Durable Materials and Construction: A Field Guide

This quick guide helps decode specs and align them with recognized durability concepts and tests [21][22][4][5].

Metals: Stainless, Brass, and High‑Carbon Steels

- 304 vs 316 stainless: Choose 316 near saltwater or corrosive environments; 304 suits most general uses.

- Brass: Prefer solid over plated for refinishability and wear life.

- High‑carbon steels: Superior edge retention and toughness, but require anti‑corrosion care.

- Look for coatings and finishes tied to salt-spray/corrosion test families (e.g., ASTM B117 context) and abrasion resistance disclosures [23][4].

Woods: Solid Hardwoods and Humidity Control

- Species: White oak, maple, walnut are common heirloom choices. Confirm solid construction and compatible joinery.

- Environmental control: Target indoor RH ~35–55% to manage seasonal movement; finish both sides of panels where possible.

- Janka hardness values and the Wood Handbook can guide species selection and expectations [8].

Leather and Textiles: Thickness, Stitching, and Abrasion

- Leather: Full‑grain 1.2–2.0 mm+; LWG-rated tanneries offer traceability and chemical stewardship [7].

- Stitching: 6–8 SPI for many full‑grain builds; reinforce stress points.

- Textiles: Disclose abrasion tests with method (ISO 12947 Martindale or ASTM D4157 Wyzenbeek) and match spec to use case [13][14].

Finishes and Coatings That Last

- Powder coat: Durable and uniform for metals; look for adhesion and abrasion resistance disclosures.

- Oil/wax: Repairable and tactile for wood; reapply periodically.

- Lacquer/varnish: Higher initial protection; may require professional refinishing.

Tie finish claims to recognized abrasion/chemical resistance test families where possible [4][5].

Environment Matters: Moisture, Heat, UV

- Coastal: Favor 316 stainless, marine finishes, and diligent rinsing

- High heat: Use heat‑tolerant alloys and finishes; avoid adhesives in load-bearing zones

- UV exposure: Specify UV‑stable textiles and coatings; reproof on schedule

Environmental exposure is addressed in relevant ISO/ASTM test families; specs should reflect intended use conditions [5][4].

Category Longevity Playbooks + TCO Calculator

Durable choices reduce waste and cost over time. Furniture and furnishings alone generated more than 12 million tons of U.S. waste in 2018 [25], and global e‑waste continues to rise [1]. Independent testing (Consumer Reports, Wirecutter) helps ground expectations and maintenance commitments [24][2].

Cookware: Cast Iron vs. Nonstick

- Why cast iron lasts: It can be re‑seasoned indefinitely; no fragile coating to fail. Nonstick pans often degrade within ~5 years [2].

- Care cadence: Season initially; light oil after each use; deep re‑season quarterly or as needed.

- TCO: One heirloom‑grade cast iron pan maintained over decades typically beats repeated nonstick replacements.

Furniture: Solid Hardwood and Joinery

- Specs: Solid hardwood frames; dovetails and mortise‑and‑tenon; hardwood species fit use and finish [3][8].

- Care: Maintain indoor humidity, refresh finish as needed (oil/wax: 6–12 months; film finishes: years to decades).

- TCO: Quality furniture can be refinished and repaired—often cheaper over 20–30 years than multiple budget replacements.

Bags & Leather Goods: Full‑Grain, Stitch Density, Hardware

- Specs: Full‑grain 1.2–2.0 mm+, saddle stitching at stress zones, solid brass/stainless hardware, serviceable fasteners.

- Care: Clean seasonally; condition 2–4× per year depending on climate; re‑stitch high‑wear zones as needed.

- Traceability: Prefer LWG-rated tanneries and disclosed finish/chemistry where skin contact is frequent [7].

Outerwear: Fabric Specs and Repair Programs

- Specs: High-denier nylon/Cordura; reinforced seams; zippers with replaceable sliders.

- Abrasion: Seek clear Martindale or Wyzenbeek benchmarks, matched to expected use [13][14].

- Care: Wash per tech-fabric guidance; reproof DWR coatings seasonally or as performance wanes.

Tools & Electronics: Modularity, Batteries, and Support Windows

- Specs: Standard fasteners; modular parts; published service manuals and parts catalogs with fair pricing.

- Software: Confirm OS/security update windows before purchase; weigh TCO with battery replacements.

- Rights: EU Right to Repair materials explain how policy can extend usable life; iFixit repairability resources help with model-level insights [19][10].

The Bravewood Difference: Durability Protocol and Transparency Ledger

We don’t just talk about heirloom quality—we codify it and publish the proofs.

Material and Construction Standards (The Bravewood Standard)

- Minimum specs across categories: 304/316 stainless, solid brass, full‑grain leather (1.2–2.0 mm+), solid hardwoods with appropriate joinery, textile abrasion benchmarks aligned to use.

- Supplier audits: Public BOMs, FSC- and LWG‑backed sourcing, OEKO‑TEX disclosures where applicable [6][7][9].

- Batch traceability: Serial numbers linked to inspection logs and QA checkpoints.

Test-Backed Claims: Third‑Party Labs and Protocols

- Methods: We align to recognized ASTM/ISO families and specify designations (e.g., corrosion fog exposure, abrasion protocols, tensile/tear) suited to the product’s intended environment [4][5].

- Evidence: Teardowns, macro photos, and test‑setup imagery accompany pass/fail thresholds to make claims replicable.

Lifetime Service: Parts, Repairs, and Turnaround SLAs

- Parts availability: Target 10+ years where technically feasible; publish parts lists and pricing.

- Repairs: Document average turnaround times and resolution rates; maintain before/after galleries for common repairs.

- Access: Clear service request flow with human support and recommended care tools.

Maker Lineage and Workshop QA

- Craft Lineage Map: Maker bios with years in trade, apprenticeship histories, and technique portfolios, informed by recognized craft frameworks [15][16][18].

- QA: Date‑stamped process media, checkpoints by stage, and serialized inspection logs linked to each product.

Benchmarking vs. ‘Buy It For Life’ Leaders

- Methodology: Side‑by‑side comparisons use equalized use cases, standardized tests, and teardown metrics. We align procedures with independent testing best practices for comparability [24][2].

- Transparency: We publish the methods and the data so third parties can evaluate outcomes.

Bravewood Legacy and Entity Clarity

- Heritage: We maintain a dated timeline and founders’ letter, with verified coverage and memberships.

- Structured data: Organization, Brand, Product, and Article markup strengthen identity clarity across platforms [11][26].

Care That Preserves Value: Long-Term Maintenance for Heirloom Goods

Durability is a partnership between build quality and owner care. Evidence-based maintenance reduces failure risk and extends service life [21].

Care Schedules by Material

- Wood: Dust monthly; refresh oil/wax 6–12 months; monitor humidity seasonally; refinish film coats as needed.

- Leather: Wipe down quarterly; condition 2–4× per year (more in arid/salty environments); avoid heat sources.

- Textiles: Clean per label; reproof technical fabrics seasonally; repair snags early.

- Metals: Clean and dry after exposure; oil high‑carbon steels; inspect coatings annually.

Adjust cadence for environment (humidity, UV, salt air) and use intensity.

Storage, Documentation, and Provenance

- Storage: Avoid basements/attics with extreme humidity/heat; use breathable covers for leather/wood.

- Documentation: Keep receipts, BOMs, certifications, and service logs (with photos of serials) in secure backups. Documentation supports warranty claims and preserves resale/transferable value.

DIY vs. Professional Repair

- DIY: Consumables and light service (conditioning, zipper pulls, reproofing, hardware swaps) when documented and tool‑appropriate.

- Pro: Structural repairs, finish restoration, electrical/mechanical faults, or anything safety‑critical.

- Always consider safety and warranty implications; when in doubt, consult qualified professionals.

FAQs: Heirloom Quality, Warranties, and Longevity

- Is there a legal definition of “heirloom quality”?

- Which materials actually last generations?

- How can I avoid planned obsolescence?

- Do “lifetime” warranties mean lifetime?

- Read exclusions and ask for service metrics (turnaround, resolution rates). Look for parts availability windows and clear, documented repair pathways [12].

- Is cast iron really “buy it for life”?

- With basic seasoning and care, yes; nonstick typically lasts far fewer years [2].

- How do I verify a brand’s generational craftsmanship claims?

Conclusion

When products become heirlooms, it’s because design, materials, construction, and care are all aligned—and transparent. The Bravewood Heirloom Readiness Standard helps you separate marketing from measurable quality with a cross‑category, test‑backed rubric. Our Durability Protocol and Transparency Ledger show the work: materials and construction standards, third‑party testing, maker lineage, and lifetime service.

Ready to buy better—once? Download the Heirloom Readiness Checklist and Scorecard, then explore the Bravewood Standard to see our test data, craft lineages, and service commitments in action.

Disclaimer

Information is provided for educational purposes only. Product maintenance and repairs carry risk—consult qualified professionals as needed. Warranty terms and standards references may change; verify current details with manufacturers and standards bodies.

References

- United Nations Institute for Training and Research (UNITAR), International Telecommunication Union (ITU), & International Solid Waste Association (ISWA). (2024). The Global E-waste Monitor 2024. Retrieved from https://globalewaste.org/reports/global-e-waste-monitor-2024/

- The New York Times Wirecutter Staff. (n.d.). Best Buy-It-For-Life Wirecutter Products. The New York Times Wirecutter. Retrieved from https://www.nytimes.com/wirecutter/reviews/best-buy-for-life-wirecutter-products/

- This Old House. (n.d.). How Heirloom Furniture Is Built. Retrieved from https://www.thisoldhouse.com/furniture/21018437/how-heirloom-furniture-is-built

- ASTM International. (n.d.). Standards and Publications. Retrieved from https://www.astm.org/

- International Organization for Standardization (ISO). (n.d.). Standards. Retrieved from https://www.iso.org/standards.html

- Forest Stewardship Council (FSC). (n.d.). About FSC and Certification. Retrieved from https://www.fsc.org/

- Leather Working Group (LWG). (n.d.). About LWG and Tannery Standards. Retrieved from https://www.leatherworkinggroup.com/

- Forest Products Laboratory, U.S. Department of Agriculture. (2010). Wood Handbook: Wood as an Engineering Material (FPL-GTR-190). Retrieved from https://www.fpl.fs.usda.gov/documnts/fplgtr/fplgtr190/fplgtr190.pdf

- OEKO-TEX Association. (n.d.). STANDARD 100 by OEKO-TEX. Retrieved from https://www.oeko-tex.com/en/our-standards/standard-100

- iFixit. (n.d.). Repairability Scores and Teardowns. Retrieved from https://www.ifixit.com/repairability

- Schema.org. (n.d.). Schema.org Vocabulary (Organization, Brand, Product, Article). Retrieved from https://schema.org/

- Darn Tough. (n.d.). Unconditional Lifetime Guarantee. Retrieved from https://darntough.com/pages/guarantee

- International Organization for Standardization (ISO). (n.d.). ISO 12947-2: Textiles — Martindale method. Retrieved from https://www.iso.org/standard/36262.html

- ASTM International. (n.d.). ASTM D4157: Standard Test Method for Abrasion Resistance of Textile Fabrics (Oscillatory Cylinder Method). Retrieved from https://www.astm.org/d4157-13.html

- American Craft Council. (n.d.). About Craft and the ACC. Retrieved from https://www.craftcouncil.org/

- United Nations Educational, Scientific and Cultural Organization (UNESCO). (n.d.). Intangible Cultural Heritage. Retrieved from https://ich.unesco.org/

- Ingold, T. (2011). The Perception of the Environment: Essays on Livelihood, Dwelling and Skill. Routledge. Accessible excerpt retrieved from https://leiaarqueologia.files.wordpress.com/2017/08/the-perception-of-the-environment-tim-ingold.pdf

- Crafts Council (UK). (n.d.). About and Apprenticeship Resources. Retrieved from https://www.craftscouncil.org.uk/

- European Commission. (n.d.). Right to Repair. Retrieved from https://environment.ec.europa.eu/topics/circular-economy/right-repair_en

- Wikipedia Contributors. (n.d.). Planned obsolescence. Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Planned_obsolescence

- U.S. Department of Housing and Urban Development. (2000). Durability by Design: A Guide for Residential Builders and Designers. Retrieved from https://www.huduser.gov/portal/publications/durability_by_design.pdf

- Strata Global. (n.d.). Durability (definition and factors). Retrieved from https://www.strataglobal.com/glossary/durability/

- ASTM International. (n.d.). ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus. Retrieved from https://www.astm.org/b0117-19.html

- Consumer Reports. (n.d.). Research & Testing at Consumer Reports. Retrieved from https://www.consumerreports.org/cro/about-us/researchtesting

- U.S. Environmental Protection Agency (EPA). (n.d.). Facts and Figures about Materials, Waste and Recycling. Retrieved from https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling

- Google Search Central. (n.d.). Organize your site structure. Retrieved from https://developers.google.com/search/docs/fundamentals/organize-your-site-structure