Introduction

In a world of disposable consumer culture—where short product lifespan is baked into design—Bravewood takes a different path. We build objects meant to be used, repaired, and cherished, so they gain character as you live with them. That character has a name: patina. It’s the graceful surface evolution that records your daily rituals—not damage, but a story.

This guide turns heirloom quality from a vague promise into a measurable, owner-ready system. You’ll get a transparent look at our materials and finishes, the science behind how Bravewood products develop patina, a finish-specific maintenance planner, restoration decision trees, and sustainability data aligned with global standards. Along the way, we’ll point you to tools you can use right now: the Bravewood Heirloom Index checklist, a seasonal care planner, a transfer certificate for heirs, and a simple total-cost-of-ownership (TCO) calculator.

- Introduction

- Bravewood Products at a Glance: Craftsmanship, Materials, Finishes, and Warranty

- Patina of Purpose: How Bravewood Products Develop Patina

- The Bravewood Heirloom Index: Turning ‘Heirloom Quality’ into Measurable Criteria

- Caring for Bravewood Wooden Goods: The Finish-Specific Maintenance Planner

- Restoration and Refinishing: Preserve Patina, Repair With Confidence

- Sustainable Materials and Anti‑Disposable Design

- The Bravewood Ownership Lifecycle: From Purchase to Generational Transfer

-

FAQs: Your Top Questions Answered

- What categories of products does Bravewood make and what materials are used?

- How do Bravewood’s finishes and construction choices affect longevity and patina?

- What humidity and temperature are best for Bravewood wooden goods?

- How can I accelerate or slow patina safely?

- When should I touch up versus fully refinish a Bravewood piece?

- Is heirloom quality more sustainable and cost‑effective long term?

- Where can I buy Bravewood products and what are lead times or custom options?

- Conclusion

- Disclaimer

- References

Bravewood Products at a Glance: Craftsmanship, Materials, Finishes, and Warranty

What We Make and Why It Lasts: Materials and Construction Choices

Bravewood products span solid-wood furniture and accessories, select leather goods, and metal-accented hardware. We prioritize sustainably sourced hardwoods (with FSC-certified options where available), mechanically robust joinery, serviceable hardware, and finishes chosen for both repairability and patina-friendly aging [20].

- Woods: We select stable, durable hardwood species and mill for grain orientation that resists warping. Our designs accommodate wood movement—an inherent behavior as wood exchanges moisture with the environment—through proven joinery and expansion allowances, guided by fundamentals documented by the USDA Forest Products Laboratory (USDA FPL) [1].

- Joinery: Expect time-tested methods like mortise-and-tenon, dovetails, and floating panels, backed by reversible adhesives where appropriate to support future restoration.

- Metals: Solid brass, stainless steel, or patina-capable alloys are chosen for repairability and graceful surface change.

- Leather: Full-grain leathers are favored for longevity and a rich patina with conditioning.

- Sourcing: Responsible wood sourcing is central to our bill of materials; look for FSC documentation on relevant products [20].

- Serviceability: Components subject to wear are modular and replaceable when possible—screws over glue, accessible fasteners, and spare parts availability.

Finishes and Patina Potential: How Surface Choices Age Gracefully

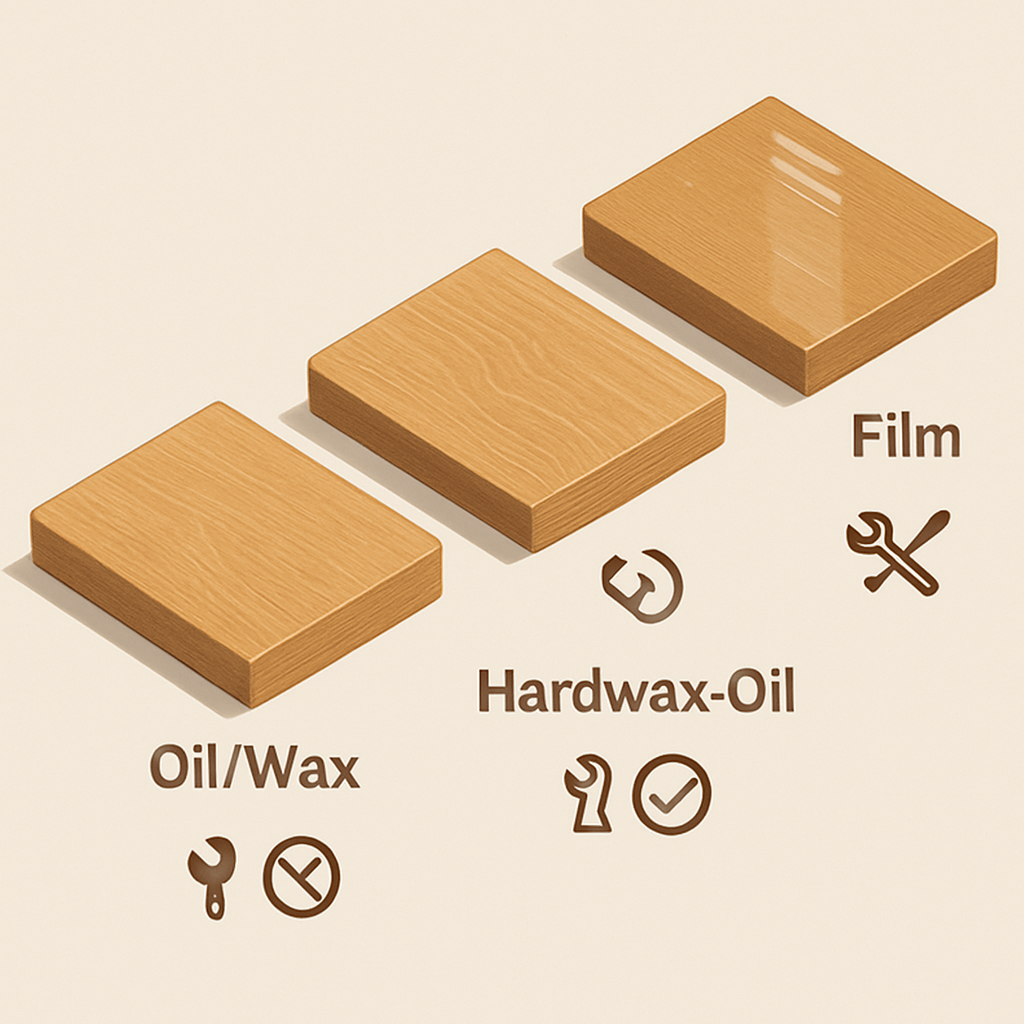

Finishes determine both how a surface feels on day one and how it ages. We use three main finish families, each validated against recognized durability frameworks to balance repairability, chemical/abrasion resistance, and patina character:

- Oil/Wax: Warm, tactile, and the most repairable. Micro-abrasions and hand oils create a mellow sheen over time—ideal if you love visible patina. Lower initial chemical/abrasion resistance than film finishes, but easy spot repair supports long-term beauty (ASTM D4060, D1308 provide common ways to frame abrasion and chemical resistance claims) [3][4]. Conservation guidance notes that aged finishes can be cleaned and renewed without stripping when handled properly [5].

- Hardwax-Oil: A middle path with improved protection while remaining patch-repairable. Expect ambering and soft luster to develop in high-touch areas.

- Film-Forming (Varnish/Lacquer): Highest initial chemical/abrasion resistance and easiest daily care, but repairs can be more involved. With time, films can micro-craze or amber; careful maintenance preserves clarity (again, benchmarked against abrasion and chemical resistance test methods) [3][4][5].

Where to Buy, Lead Times, and Custom Options

You can purchase Bravewood products through our direct online storefront and select partner showrooms. Typical lead times range from 4–12 weeks depending on seasonality and customization. Custom options include dimensions, wood species, and finish choice; custom finish selections ship with the relevant Safety Data Sheets (SDS) and Technical Data Sheets (TDS) plus tailored care guidance to protect both performance and patina.

Warranty and Heirloom Transfer

Our warranty covers defects in materials and workmanship under normal residential use. We celebrate acceptable patina—small sheen changes, fine micro-scratches, color mellowing—as a sign of a life well lived. Damage includes deep gouges into wood fibers, finish-failing spills left standing, heat burns, splitting from extreme humidity exposure, or misuse.

- Care expectations align with preventive conservation principles: stable environment, safe cleaning, and timely minor maintenance preserve integrity and value [2].

- To support heirloom transfer, each piece ships with a serial-numbered provenance card and care logbook. When you pass it on, the new owner receives documented history, any service records, and next-service recommendations.

Patina of Purpose: How Bravewood Products Develop Patina

What Is Patina? Wood, Leather, and Metal Compared

Patina is the visible result of time, use, and environment shaping a material’s surface. On wood, it blends subtle oxidation, ultraviolet (UV) light exposure, finish ambering, micro-abrasion, and hand oils into a richer depth of color and sheen [5]. Leathers develop deepened tones and a buttery hand through oxidation and conditioning. Metals undergo surface oxidation or controlled chemical reactions that create stable, decorative films—the classic “verdigris” on copper or warm browns on brass—rooted in well-understood oxidation/corrosion principles [6].

Environment Matters: Sunlight, Humidity, and Handling

Three factors steer patina—and, if unmanaged, risk damage:

- Sunlight (UV): Encourages color change and finish ambering. Manage exposure to prevent stark tan lines: diffuse light, rotate objects periodically, and use shading where needed [5].

- Relative Humidity (RH) and Temperature: Wood expands as it absorbs moisture and contracts as it dries. Sustained extremes or rapid swings stress joinery and finishes. Target a stable indoor RH roughly in the 35–55% band with moderate temperatures to minimize movement and finish stress; monitor with a simple hygrometer [1].

- Handling and Contact: Natural hand oils, micro-dust abrasion, and daily use develop luster. Use soft pads under accessories, lift rather than drag objects, and clean grit before wiping to keep patina graceful rather than scratchy [2].

Patina vs Damage: A Plain-Language Policy with Examples

- Graceful patina: soft sheen in high-touch zones, slight color mellowing where sunlight falls, micro-scratches that do not break through the finish.

- Damage: standing water rings that penetrate and blush the finish, heat marks, deep cuts into wood fibers, film failure (peeling/crazing), or cracks from severe RH swings.

Wear is a fundamental life-limiting mechanism; managing abrasion and contact loads increases service life, a core insight of tribology (the study of friction, wear, and lubrication) taught in engineering contexts such as MIT OpenCourseWare [18]. Our warranty recognizes patina as normal and desirable; damage triggers repair or pro restoration. See our photo library index for side-by-side examples mapped to warranty boundaries.

Manage the Look: Encourage, Preserve, or Slow Patina Safely

- To encourage patina (wood/leather): Use the piece; keep surfaces clean of grit; condition leather with a finish-compatible product at the recommended interval. Avoid harsh chemicals that strip character; follow AIC-safe cleaning guidance for finished wood [2].

- To preserve/slow patina: Diffuse direct sunlight, rotate surfaces quarterly, use coasters and trivets, and clean with pH-neutral, finish-safe solutions. Maintain target RH and avoid rapid seasonal swings [1][2].

- Metal accents: If you want a deeper patina or specific tone, use only vetted patina chemistries with SDS/TDS in a well-ventilated space and proper PPE; follow product guides carefully to avoid over-etching and to neutralize reactions [7][8]. When in doubt, test on an inconspicuous area first.

The Patina Lookbook

We maintain time-lapse galleries of Bravewood finishes aging under varied conditions (low vs high UV, 35% vs 55% RH, different finish families). Each sample documents:

- Wood species and finish

- UV-hours exposure and RH/temperature bands

- Care routine used (cleaning interval, any conditioning)

- Any finish brand TDS consulted to set recoat/refresh parameters

This rigor helps you set realistic expectations for color shift and sheen, so patina feels like a feature—not a surprise.

The Bravewood Heirloom Index: Turning ‘Heirloom Quality’ into Measurable Criteria

The Rubric: Materials, Construction, Finish, Serviceability, Documentation, Sustainability

We score every Bravewood product across six categories (0–10 each; 60-point total):

- Materials Grade: FSC-eligible hardwoods, metal alloys chosen for longevity and repairability [20].

- Construction: Joinery that accommodates movement; stress-tested designs; fasteners that can be serviced [1].

- Finish Repairability and Durability: Ability to spot-repair, recoat, or refinish; framed against recognized test methods for abrasion, chemical resistance, adhesion, and hardness (ASTM D4060, D1308, D3359, D4366) [3][4][9][10].

- Serviceability: Parts catalog, standardized fasteners, rework-friendly assemblies, and published lead times for components.

- Documentation: Serial-numbered provenance, batch logs, SDS/TDS, and a care logbook—key trust signals echoed in conservation practice [2].

- Sustainability: ISO 14040/14044-aligned LCA disclosures, responsible sourcing, low-VOC finishes, and take-back/refurbishment pathways [11][12].

Example: A representative dining table scores high on materials, construction, and documentation; finish score varies by your choice (oil/wax yields top repairability; film finish offers top initial resistance; both can achieve strong totals).

Verify Before You Buy: A Shopper’s Checklist

Ask these questions to confirm heirloom quality:

- What wood species and certifications back the sourcing (FSC certificate available)? [20]

- What joinery holds primary loads? Are panels allowed to move seasonally?

- What finish is used, and how is it repaired or renewed? Are SDS/TDS provided?

- Are spare parts and touch-up kits available? What are typical lead times?

- Is there a clear warranty that distinguishes patina from damage?

- Does the maker publish LCA or durability data, aligned to recognized frameworks (WRAP, Ellen MacArthur Foundation, ISO)? [14][13][11][12]

Ownership Toolkit: Provenance, Transfer Certificates, and Care Logbook

Your toolkit includes:

- Serial-numbered provenance card and batch details for traceability

- Care logbook to record environment, cleanings, minor repairs, and any professional service (conservation documentation principles improve value retention) [2]

- Transfer certificate template to pass history, spare parts, and next-service recommendations to the next owner

Total Cost of Ownership: Buy Once, Maintain for Life

A durable, repairable product typically lowers TCO by reducing replacement cycles, maintaining performance, and preserving resale value. Methodologically, we align environmental accounting to ISO 14040/14044 LCA principles—defining a functional unit, boundaries, and impact categories—to compare a Bravewood piece maintained over decades against multiple disposable alternatives [11][12]. Leading circular-economy guidance (Ellen MacArthur Foundation, WRAP) consistently shows longevity and repairability as powerful levers for reducing waste and impact [13][14]. At a macro level, the environmental cost of throwaway habits is well documented, underscoring the importance of buying well and maintaining intentionally [15][16].

Caring for Bravewood Wooden Goods: The Finish-Specific Maintenance Planner

Environment Targets and Monitoring

- Target RH: 35–55% with minimal daily/seasonal swings; Temperature: moderate, stable indoor ranges. These conditions reduce wood movement and finish stress [1].

- Placement: Avoid direct heat sources and intense, unfiltered sunlight. Use curtains, UV-diffusing shades, or rotate pieces seasonally to balance exposure [5].

- Monitoring: A basic hygrometer and thermometer provide early warning; adjust via humidifiers/dehumidifiers as needed.

Cleaning and Conditioning by Finish Type

- Oil/Wax: Dust weekly with a soft, dry cloth. Clean monthly with a pH-neutral, finish-safe cleaner; replenish oil/wax as sheen dulls or annually. Follow AIC guidance for safe agents, apply thinly, and buff after curing [2]. Always consult and retain SDS/TDS; patch-test in an inconspicuous spot first.

- Hardwax-Oil: Dust weekly; damp wipe monthly with a mild cleaner; use manufacturer-compatible refreshers when micro-scratches accumulate. Annual or as-needed refresh keeps luster.

- Film-Forming Finishes: Dust weekly; damp wipe with mild cleaner as needed. Avoid abrasive pads and solvents that can cloud or soften films. Minor rub-out/polish can restore gloss; deeper damage may require professional touch-up or localized recoat.

Troubleshooting Tree: Rings, Scratches, and Dullness

- Water rings (white blush): For oil/hardwax-oil, try a light re-oil and buff; escalate to gentle abrading and refresh coat if needed. For films, test heat/humidity poultice; if unresolved, consider a localized polish or pro repair.

- Light scratches: Oil/hardwax-oil—clean, scuff with very fine abrasive, and refresh. Film—evaluate depth; shallow marks may polish out; deeper cuts may require localized fill and finish.

- Dullness: Clean first; if persistent, refresh oil/hardwax-oil or evaluate film finish for polish. Assess adhesion and hardness when planning any recoat to ensure success (ASTM D3359, D4366 provide widely used evaluation methods) [9][10].

Document each step with photos and notes in your care logbook; this aids warranty questions and future refinishing decisions.

Sunlight and Color Change: Preventing Uneven Fading

Wood and finishes undergo photo-oxidation, shifting color and sheen in light-exposed zones. Best practices:

- Diffuse direct sun with sheers or shades; consider UV-filtering window films.

- Rotate accessories and rearrange furniture seasonally to even exposure.

- Expect and embrace gentle mellowing; use the Patina Lookbook to anticipate finish-specific changes [5].

Restoration and Refinishing: Preserve Patina, Repair With Confidence

Repair, Restore, or Refinish? The Bravewood Decision Tree

- Touch-up: For small scratches or tiny dents, finish-specific blends and stick waxes can restore continuity without disrupting patina.

- Partial restore: For localized film wear, abrade and recoat just the affected zone when adhesion supports it.

- Full refinish: For widespread film failure, deep stains, or incompatible prior repairs, strip and refinish—preserving patina cues where possible (mask witness marks, avoid over-sanding edges).

- Pro conservation: For high-value pieces or complex finishes, hire a professional conservator following ethical guidelines to retain original material and character [2][19].

We document before/after case studies with process steps, product specs, and outcomes to help you choose the right path while protecting warranty and value.

Finish Compatibility: Recoating Without Stripping

- Oil/Wax and Hardwax-Oil: Designed for renewability; light abrasion and reapplication typically suffice. Respect recoat windows and prep from finish TDS.

- Film Finishes: Recoat success hinges on surface prep and adhesion. Conduct a simple adhesion check before committing to a recoat; if it fails, stripping may be necessary for durable results (ASTM D3359 is a common reference for adhesion evaluation) [9].

Tools, Safety, and PPE

- Essentials: Dust extraction, respirator with appropriate cartridges, gloves, eye protection, and clean, lint-free cloths.

- Safety: Always consult SDS/TDS for hazard and PPE guidance; many solvents and patina agents require ventilation and strict handling. Dispose of rags and finishes per local regulations to prevent fire hazards and environmental harm [19].

When to Hire a Professional and What to Ask

- Consider a pro when damage is extensive, finishes are complex, or the piece carries high sentimental or market value.

- Ask for: Scope of work, methods and materials (with SDS/TDS), how patina will be preserved, expected timelines, and warranty on workmanship. Look for credentials and portfolios consistent with conservation-oriented practice [2].

Sustainable Materials and Anti‑Disposable Design

Design for Longevity: Modular Parts, Repairability, and Finish Renewability

We design to counter short product lifespan:

- Modular, replaceable parts with standard fasteners

- Accessible assemblies that can be disassembled and serviced

- Finishes with renewability built in (especially oil and hardwax-oil options)

- Published parts catalog and service lead-time targets

These principles align with the broader Right to Repair movement that promotes access to parts and information so owners can maintain long-lived goods [17].

Life Cycle Assessments (ISO 14040/44) and Real Impacts

We use ISO 14040/14044 as our methodology for product LCAs, disclosing:

- Functional unit (e.g., one table over 25 years of service)

- System boundaries (raw materials through end-of-life scenarios)

- Key impact categories (e.g., GWP, energy, water)

- Data sources, quality, and limitations

Results inform material choices, finish selection, packaging, and refurbishment pathways—so the lowest-impact choice is also the longest-lived [11][12].

Countering Disposable Consumer Culture

Planned obsolescence and throwaway norms generate staggering waste. The UN Environment Programme highlights the need for sustainable consumption and production shifts, with longevity as a crucial lever [15]. Earth.org reports fast fashion alone creates tens of millions of tons of waste annually—a cautionary signal across categories [16]. Bravewood’s Ownership Lifecycle model—durability, repairability, published parts, and heirloom transfer—translates circular-economy principles into daily practice [13][14].

End‑of‑Life: Refurbish, Reuse, or Recycle

When a product reaches a crossroads:

- Refurbish: Refresh finishes, replace worn parts, and return to service with renewed life.

- Reuse: Repurpose components or donate to extend utility.

- Recycle: Disassemble to material streams where possible; we provide materials identification to assist recyclers.

These steps mirror circular strategies advocated by the Ellen MacArthur Foundation—keeping materials in use at their highest value for as long as possible [13].

The Bravewood Ownership Lifecycle: From Purchase to Generational Transfer

Onboarding: Provenance, Setup, and QR‑Linked Micro‑Instructions

Your serial-numbered provenance card anchors documentation from day one—log delivery date, room environment, and any setup notes. Scan the QR on your card to access finish-specific micro-instructions, SDS/TDS, and care videos. Conservation practice underscores the value of documentation for long-term stewardship and value preservation [2].

Maintenance Cadence and Automated Reminders

Adopt a seasonal cadence:

- Quarterly: Dust, gentle clean, rotate surface accessories, visual inspection, quick environment check

- Biannual: Deeper clean; refresh oil/hardwax-oil finishes as indicated; tighten accessible fasteners

- Annual: Full condition review, photo documentation, and update care logbook

Optional smart sensors can alert you to RH/temperature thresholds to protect wood stability [1].

Wear vs Damage: Warranty Boundaries and Service Triggers

Use the plain-language policy and photo library as your guide. When you see red flags—film failure, deep gouges, spreading water stains—stop DIY and contact support or a vetted pro. Tribology principles remind us that early intervention against abrasive wear and surface failure dramatically extends service life [18].

Parts, Touch‑Up Kits, and Vetted Restoration Partners

We maintain a parts catalog with availability commitments, factory-matched touch-up kits by finish, and a vetted partner directory for repairs and refinishing. This aligns with Right to Repair ideals: timely access to parts and information keeps products in service longer [17].

Heirloom Transfer: Documentation and Care Continuity

When it’s time to pass your Bravewood piece on:

- Include the provenance card, care logbook, any service receipts, and spare parts

- Add a completed transfer certificate with next-service recommendations and current environment notes

- Encourage the new owner to continue the log—a conservation-minded continuum that maintains value and care knowledge [2]

FAQs: Your Top Questions Answered

What categories of products does Bravewood make and what materials are used?

We build solid-wood furniture and accessories, with select leather goods and metal-accented components. Our wood program prioritizes responsibly sourced hardwoods (FSC where available), and we publish finish VOC information alongside SDS/TDS for transparency [20]. See each product’s spec sheet for exact species, finish, and hardware.

How do Bravewood’s finishes and construction choices affect longevity and patina?

Joinery that allows wood to move seasonally, plus serviceable hardware, underpins longevity. Finish choice then tunes daily care and patina character: oil/wax is most repairable and patina-forward; hardwax-oil blends renewability and protection; film finishes maximize initial resistance. We reference widely used test frameworks—abrasion (ASTM D4060) and chemical resistance (ASTM D1308)—when describing performance, and conservation literature for caring for aged finishes [3][4][5].

What humidity and temperature are best for Bravewood wooden goods?

Aim for stable indoor conditions with RH around 35–55% and moderate temperatures. Avoid rapid swings. These ranges mitigate wood movement and finish stress; monitor with a hygrometer and adjust seasonally [1].

How can I accelerate or slow patina safely?

- Wood/leather: Use the piece, keep grit off surfaces, and condition per finish; to slow, manage light exposure and stick to pH‑neutral cleaners. Follow AIC’s safe care principles [2].

- Metals: For stronger or specific patina tones, use vetted patina solutions with proper PPE and strict adherence to SDS/TDS and process guides; always test first [7][8].

When should I touch up versus fully refinish a Bravewood piece?

Touch up minor scratches and surface dullness; refresh oil/hardwax-oil finishes as needed. Consider partial or full refinish when there’s widespread film failure, deep staining, or incompatible prior repairs. Evaluate adhesion/hardness when planning recoats and seek professional help for complex cases [2][9][10].

Is heirloom quality more sustainable and cost‑effective long term?

Typically yes. Durability and repairability reduce replacement purchases (lower TCO) and environmental impacts when assessed through ISO 14040/14044 LCA principles. Guidance from WRAP and the Ellen MacArthur Foundation emphasizes longevity as a top strategy; macro data from UNEP and investigative reporting on waste underscore the urgency [11][12][14][13][15][16].

Where can I buy Bravewood products and what are lead times or custom options?

Shop directly via our website or select showrooms. Lead times average 4–12 weeks depending on the season and customization. Custom finishes include SDS/TDS and care instructions tailored to your selection to preserve performance and patina.

Conclusion

Heirloom quality isn’t a slogan at Bravewood—it’s a system you can see, measure, and use. With transparent materials and finishes, patina science you can trust, finish‑specific maintenance, restoration pathways, and ISO‑aligned sustainability, you’re equipped to buy once, maintain for life, and proudly pass it on.

Call to action: Download the Bravewood Ownership Toolkit (Heirloom Index checklist, care planner, transfer certificate, and TCO calculator), and subscribe for seasonal maintenance reminders and new patina case studies.

Disclaimer

Always follow finish manufacturer SDS/TDS and use appropriate PPE when handling chemicals or power tools. Test any cleaner or finish on an inconspicuous area first. DIY restoration can void warranties—consult Bravewood support or a certified professional when in doubt. Environmental targets (RH/temperature) are guidance, not guarantees; building conditions vary.

References

- USDA Forest Products Laboratory. (2010). Wood Handbook: Wood as an Engineering Material (FPL-GTR-190). U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. Retrieved from https://www.fpl.fs.usda.gov/documnts/fplgtr/fpl_gtr190.pdf

- American Institute for Conservation (AIC). (N.D.). Caring for Your Treasures: Wood Objects. Retrieved from https://www.culturalheritage.org/resources/consumers/caring-for-your-treasures/wood-objects

- ASTM International. (N.D.). ASTM D4060 – Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser. Retrieved from https://www.astm.org/Standards/D4060.htm

- ASTM International. (N.D.). ASTM D1308 – Standard Test Method for Effect of Household Chemicals on Clear and Pigmented Organic Finishes. Retrieved from https://www.astm.org/Standards/D1308.htm

- Smithsonian Museum Conservation Institute. (N.D.). Care of Furniture. Retrieved from https://www.si.edu/mci/english/learn_more/taking_care/furniture.html

- ASM International. (N.D.). ASM Handbooks Online: Corrosion and Surface Engineering (overview). Retrieved from https://www.asminternational.org/materials-resources/asm-handbooks

- Sculpt Nouveau. (N.D.). Patinas Product Guide (PDF). Retrieved from https://www.industrialmetalsupply.com/images/manufacturers/Sculpt%20Nouveau/Patinas%20Product%20Guide.pdf

- Birchwood Technologies. (2019). Patina Green Instructions (PDF). Retrieved from https://www.birchwoodtechnologies.com/wp-content/uploads/2019/02/7504_Patina_Green_Instructions.pdf

- ASTM International. (N.D.). ASTM D3359 – Standard Test Methods for Measuring Adhesion by Tape Test. Retrieved from https://www.astm.org/Standards/D3359.htm

- ASTM International. (N.D.). ASTM D4366 – Standard Test Methods for Hardness of Organic Coatings by Pendulum Damping Tests. Retrieved from https://www.astm.org/Standards/D4366.htm

- International Organization for Standardization (ISO). (2006). ISO 14040: Environmental management — Life cycle assessment — Principles and framework. Retrieved from https://www.iso.org/standard/37456.html

- International Organization for Standardization (ISO). (2006). ISO 14044: Environmental management — Life cycle assessment — Requirements and guidelines. Retrieved from https://www.iso.org/standard/38498.html

- Ellen MacArthur Foundation. (N.D.). What is a circular economy? Retrieved from https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview

- WRAP (UK). (N.D.). Product life extension (durability and repairability guidance). Retrieved from https://wrap.org.uk/resources/guide/product-life-extension

- UN Environment Programme (UNEP). (N.D.). Sustainable consumption and production. Retrieved from https://www.unep.org/explore-topics/resource-efficiency/what-we-do/sustainable-consumption-and-production

- Earth.org Staff. (2022). Throwaway Culture Is Drowning Us in Waste. Earth.org. Retrieved from https://earth.org/throwaway-culture-is-drowning-us-in-waste/

- Repair.org. (N.D.). Right to Repair (overview). Retrieved from https://repair.org/

- MIT OpenCourseWare. (2004). 2.800 Tribology (Fall 2004). Massachusetts Institute of Technology. Retrieved from https://ocw.mit.edu/courses/mechanical-engineering/2-800-tribology-fall-2004/

- Getty Conservation Institute. (N.D.). Conservation (overview and resources). Retrieved from https://www.getty.edu/conservation/

- Forest Stewardship Council (FSC). (N.D.). What is FSC? Retrieved from https://www.fsc.org/en