Introduction

If you’ve ever carried a wobbly dresser to the curb, you’re not alone. The U.S. sends millions of tons of furniture to landfills every year, a surge tied to “fast furniture” that looks good on day one but rarely survives a move or a few seasons of humidity changes [1] [8] [9]. At Bravewood, we believe “heirloom” shouldn’t be a buzzword—it should be a measurable standard you can verify before you buy.

This guide introduces the Bravewood Heirloom Standard: a public, test-backed benchmark for heirloom furniture that specifies solid hardwood species, moisture content targets (6–8% at shipment), grain orientation, joinery, finish chemistries, hardware, repairability, and lifelong service. You’ll also get practical tools: a buyer’s inspection checklist, a Repairability Index to compare pieces, a lifecycle cost calculator framework, and a brand comparison rubric—so you can buy once, confidently, for generations.

- Introduction

- What Makes Bravewood Heirloom Quality: Our Public, Test-Backed Standard

- Materials That Endure: Solid Hardwoods, Species, and Grain Orientation

- Heirloom-Grade Construction: Moisture Control, Joinery, and Movement

- Finishes and Hardware Built for Decades

- Repairability, Warranty, and Lifelong Service

- Fast Furniture vs. Heirloom: Durability, Waste, and True Cost

- How to Choose Furniture That Lasts Generations: A Field-Tested Checklist

- Timeless Craftsmanship and Design: What Never Goes Out of Style

- Sustainably Sourced Wood, Verified

- Best Heirloom-Quality Wooden Furniture Brands: How Bravewood Compares

- Care and Maintenance for Generational Longevity

-

FAQs: Your Most Asked Questions, Answered

- Who is Bravewood and what makes Bravewood pieces heirloom-quality?

- Which hardwoods does Bravewood use and where are they sourced?

- What joinery and finishes are used, and how do they impact longevity?

- What warranties or repair services does Bravewood offer?

- How should I care for a Bravewood piece so it lasts generations?

- How can I verify solid hardwood and quality joinery in-store?

- Which finishes last the longest and can be renewed?

- Is durable furniture more cost-effective over time?

- How do I responsibly dispose of or donate old furniture?

- Lead times, customization, and pricing for handcrafted pieces?

- Conclusion

- Disclaimer

- References

What Makes Bravewood Heirloom Quality: Our Public, Test-Backed Standard

“Heirloom” at Bravewood means construction and care standards you can measure, inspect, and service—today and decades from now. Our Heirloom Standard sets transparent, shop-floor specifications and publishes the evidence: BOM-style build specs, moisture content logs, joinery details, finish systems, hardware, QC checklists, service protocols, and sourcing certifications.

- Sourcing with integrity: We prioritize FSC and PEFC–certified hardwoods and publish our chain-of-custody documentation so you can verify responsible wood origins [3] [4].

- Construction fundamentals: Traditional joinery (mortise-and-tenon, dovetails), engineered for movement, with documented tolerances and adhesives matched to use.

- Moisture control: Wood is conditioned and verified at 6–8% moisture content at shipment for dimensional stability in typical homes.

- Finishes and hardware: Finish chemistries matched to use-case and repairability, and hardware with published cycle/load ratings from leading manufacturers.

- Proof and transparency: Certificates, MC logs, calibration checks, racking and drawer-cycle test clips, and finish resistance demos—plus a repair archive you can review.

- Lifelong service: A Repairability Index score at purchase, transferable lifetime warranty, provenance card with service history, and take-back/resale programs.

We encourage you to compare these specifics with any piece you’re considering. Resources like This Old House provide independent, plain-language guidance on the hallmarks of heirloom construction [2].

Who Bravewood Is—and Why Our Pieces Qualify as Heirlooms

Bravewood is a guild of designers, machinists, and master woodworkers who share one goal: build furniture that earns a place in a family story. We put transparency first because quality should be evident—not inferred.

Master Craft Profile

- Lead Joiner: Elena Park, 22 years in trade. Specialties: through mortise-and-tenon frames, hand-cut dovetails, movement-tolerant panel systems.

- Senior Finisher: David Mora, 18 years. Specialties: conversion varnish for tabletops, hand-rubbed oil/wax renewables, color matching and restoration.

- Shop Foreman: Luis Cabrera, 25 years. Specialties: kiln conditioning oversight, tolerance control, QC audits.

Independent craft authorities echo the fundamentals we practice: solid hardwoods, robust joinery, and smart allowances for wood movement are non-negotiables for heirloom-grade builds [2].

The Bravewood Heirloom Standard at a Glance (BOM Specs)

Here’s the essence of our BOM for casegoods and tables; every production order includes a full, serialized spec.

- Materials

- Solid North American hardwoods (typical: white oak, hard maple, walnut); panels and tops are solid, not veneer-over-MDF.

- Grain orientation: quartersawn or rift on long spans and doors for stability; careful flatsawn selections where figure is desired.

- Moisture and Conditioning

- Target MC: 6–8% at shipment; acclimation protocol and MC logs retained in job file.

- Meter calibration checks recorded by serial number and date.

- Joinery

- Frames: through or blind mortise-and-tenon, sized for racking resistance.

- Drawers: English dovetails, solid sides/bottoms; bottoms float in grooves to accommodate movement.

- Panels: floating construction with quantified clearances.

- Finishes

- Tabletops, dining, kid-heavy zones: catalyzed or conversion varnish systems tuned for abrasion/chemical resistance.

- Occasional and low-wear pieces: hand-rubbed oil/wax systems for tactile warmth and easy renewals.

- Hardware

- Slides/hinges from top-tier makers with published cycle/load ratings; solid brass or stainless hardware where appropriate; through-bolting on stress points.

- Serviceability

- Standardized fasteners and access paths, replaceable components, renewable finishes where possible, and spare-parts availability.

Download: Bravewood Heirloom Standard (PDF)

We provide a printable one-page summary with:

- Author and revision date, cross-referencing our full Standard.

- Photo callouts of joinery, underside fasteners, and finish steps.

- QC checkpoints you can bring to any showroom.

Proof and Transparency: Certificates, QC Logs, and Test Videos

- Responsible wood, verified: We publish our FSC and/or PEFC chain-of-custody references with active audit dates so you can confirm status directly with those organizations [3] [4].

- QC and test evidence: Example MC logs (shipment and arrival), moisture meter calibration checks, drawer cycle clips, racking demos, and finish abrasion/chemical spot tests—with methods summarized and full protocols available on request.

- Context from independent craft testing: Fine Woodworking’s long-running evaluation of joinery and finishes underlines why mortise-and-tenon and dovetails remain the gold standard for structural durability [5].

Materials That Endure: Solid Hardwoods, Species, and Grain Orientation

Solid hardwoods outperform veneer-over-MDF or particleboard where heirloom longevity is the goal. They tolerate repairs, refinishes, and hardware upgrades; they stiffen frames; and properly oriented grain resists seasonal movement.

Quick Janka Hardness Reference (approx.)

- Hard maple: ~1450 lbf

- White oak: ~1360 lbf

- Walnut: ~1010 lbf

Hardness informs dent resistance, particularly for tabletops and chair rails. Responsible sourcing via FSC/PEFC ensures forest stewardship and traceability alongside performance [3] [4].

Best Species for Heirlooms (With Janka Hardness Quick Reference)

- Dining tables and desks: Hard maple or white oak for dent resistance; quartersawn/rift for long spans. Finishes: conversion varnish for spill/heat resistance; oil/wax only when frequent renewal is acceptable.

- Dressers and cabinets: Walnut and white oak balance stability and beauty; dovetailed drawers in maple or oak resist wear.

- Coffee/occasional tables: Walnut or cherry (softer) acceptable with coasters/pads; oil/wax can be renewed easily.

Wood movement and finishing nuances—such as blotch-prone species or open-pore filling—are well documented by professional craft outlets like Fine Woodworking and inform our finishing schedules [5].

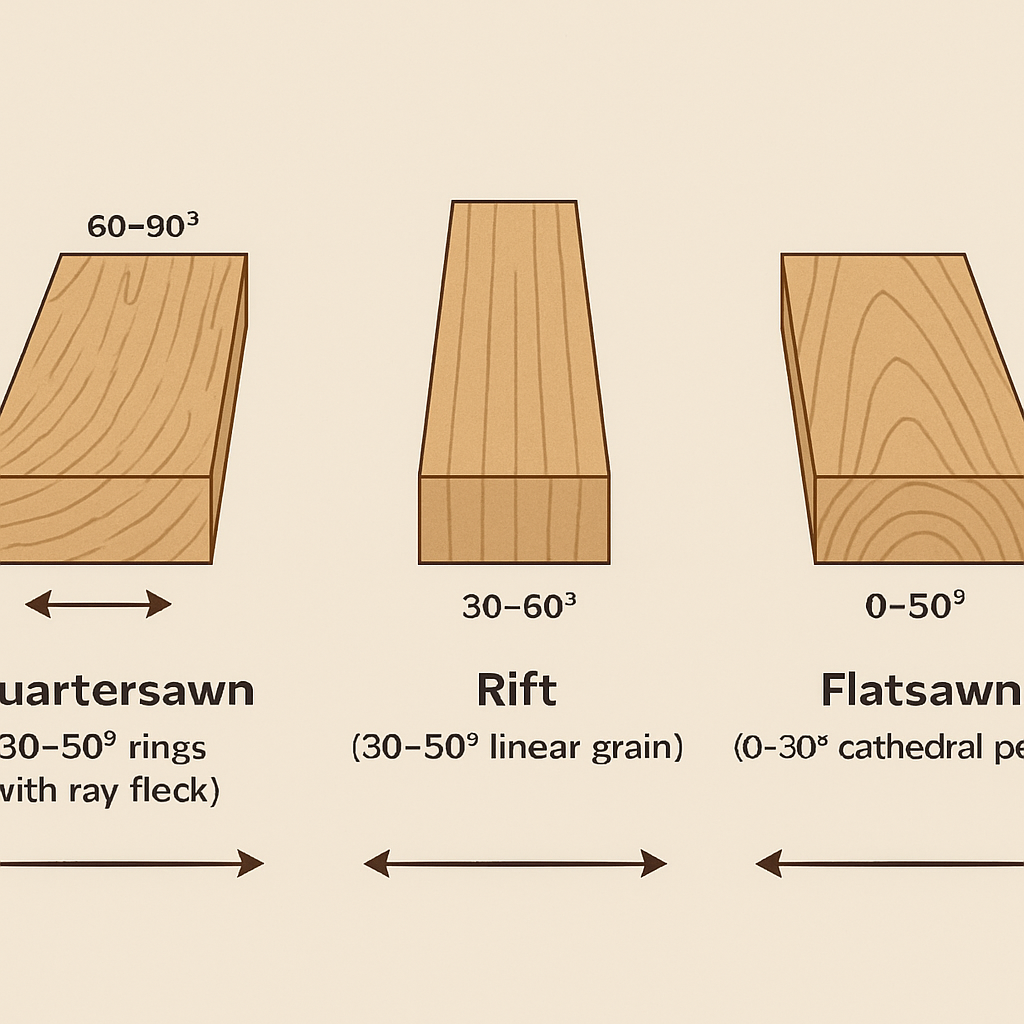

Grain Orientation 101: Quartersawn, Rift, and Flatsawn

- Quartersawn: Growth rings ~60–90° to the face; superior stability across width; signature ray fleck in oak. Ideal for doors, legs, and tabletops.

- Rift: Rings ~30–60°; very linear grain and stable; favored for legs/frames.

- Flatsawn: Rings ~0–30°; vivid cathedrals, more movement. Best for smaller components or balanced glue-ups.

Independent guides consistently show the stability advantages of quartersawn/rift stock on long spans and doors [2] [5].

Responsible Sourcing: FSC/PEFC and Chain-of-Custody

- What to verify: Certificate scope (forest management vs chain-of-custody), validity dates, and supplier names that match your invoice. Bravewood maps supplier lots to each job file so provenance is traceable.

- Why COC matters: It ensures certified wood stays identified from forest to finished piece, reducing the risk of illegal or high-risk timber [3] [4].

We also track regulatory developments that advance legality and transparency in wood trade; your documentation packet explains how we align our sourcing and records.

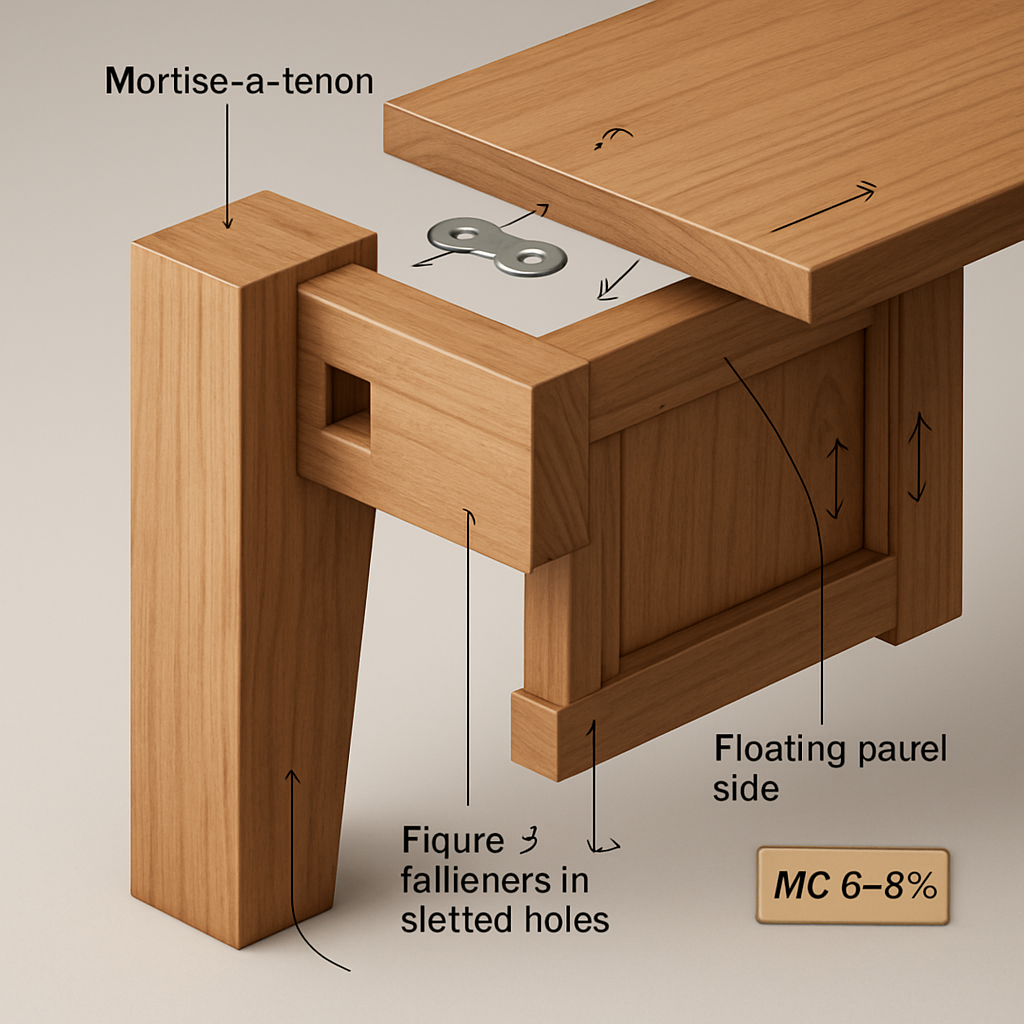

Heirloom-Grade Construction: Moisture Control, Joinery, and Movement

Durability isn’t a mystery; it’s engineering discipline. We control moisture, rely on structural joinery, and build in movement allowances across panels and tops.

Why 6–8% Moisture Content Is Non-Negotiable

Wood is hygroscopic. If furniture ships too wet or too dry relative to your home, seasonal swelling or shrinkage can telegraph as splits, warps, and joint failure. Our process:

- Conditioning and verification: Kiln schedules, shop acclimation, and MC readings logged by component and batch.

- Home environment guidance: Keep indoor relative humidity around 35–55% year-round to align with typical equilibrium moisture content for temperate homes; use humidifiers/dehumidifiers as needed and avoid heat vents/windows.

- Delivery checklist: We record MC at shipment; you can confirm upon arrival with your own meter or ours during setup.

Professional craft sources regularly underscore the link between correct MC and structural integrity [5].

Joinery That Lasts: Mortise-and-Tenon and Dovetails vs. Cam-Locks

- Mortise-and-tenon: Large glue surface area and mechanical interlock resist racking in tables, chairs, and frames.

- Dovetails: Triangular geometry locks drawer sides to the front, handling push-pull cycles for decades.

- Cam-locks and screws into particleboard: Faster to assemble but vulnerable to strip-out and loosening, particularly under movement and weight.

Independent testing and decades of shop practice explain why traditional joinery outperforms quick fasteners in long-term rigidity and serviceability [2] [5].

Designing for Movement: Floating Panels, Top Fasteners, Tolerances

- Floating panels: Panels “float” in grooves with clearances sized to panel width and species movement.

- Tabletop fasteners: Slotted or figure-8 fasteners allow tops to expand/contract across grain while staying centered.

- Tolerances: We publish clearance targets by panel width and climate band, and we verify slotting during QC.

These strategies, long advised by trusted building authorities, are essential to prevent splits and frame stress [2].

Finishes and Hardware Built for Decades

Finish chemistry and hardware selection should match the job—and make future repairs straightforward.

Finish Systems by Use-Case: Dining, Kids’ Rooms, and Occasional Pieces

- Dining/desk/tabletops: Conversion or catalyzed varnishes for superior abrasion, chemical, and heat resistance. We publish MSDS/specs and our abrasion/spot test methodology with result summaries.

- Kids’ rooms and high-touch items: Durable film finishes or hybrid systems for easy cleanup and impact resistance.

- Occasional/low-wear: Hand-rubbed oil/wax for unmatched touch and quick renewals—expect more frequent maintenance.

Craft testing and finish shootouts highlight durability vs renewability tradeoffs; we align systems with realistic use and care patterns [5].

Hardware That Goes the Distance

- Slides and hinges: We spec premium hardware with manufacturer cycle ratings (often 50,000–100,000+ cycles) and load data. You’ll see part numbers in your BOM.

- Pulls and knobs: Solid brass or stainless where suitable; through-bolting on heavy-use doors/drawers.

- Inside-the-cabinet execution: Backplates and proper pilot sizing prevent tear-out; we publish torque specs for re-tightening during annual checks.

Repairability by Design

- Replaceable parts: Drawer boxes, slides, pulls, glides, and adjustable shelves are standardized and replaceable.

- Reversible choices: We favor mechanical fasteners where access is needed and finishes that can be renewed in place when possible.

- Spare parts: We maintain inventory for current lines and provide compatible alternatives for legacy pieces; your provenance card tracks part compatibility and service history.

Repairability, Warranty, and Lifelong Service

The difference between a long-lasting object and a true heirloom is what happens after delivery. We design for repair, publish a Repairability Index score, stand behind a transferable lifetime warranty, and operate take-back/resale programs.

Introducing the Bravewood Repairability Index

Our transparent score helps you compare pieces across makers:

- Joinery accessibility (0–10): Can stressed joints be accessed and repaired without destructive disassembly?

- Finish renewability (0–10): Can the surface be renewed in place with minimal masking and downtime?

- Parts availability (0–10): Are slides, hinges, pulls, and glides standardized and replaceable a decade from now?

- Documentation and fasteners (0–10): Are BOM, torque specs, and fastener maps provided to owners/technicians?

- Total (0–40): Higher is better, and we publish rationale per model.

“As a restorer, I look for parts you can source, finishes you can renew, and joints you can reach. Design those in, and you add decades of life.”

Transferable Lifetime Warranty and Provenance Card

- Coverage: Structural integrity of frames and joinery under normal residential use; finish/cosmetic coverage varies by system and environment; exclusions summarized in the policy.

- Transferability: Warranty transfers with the piece when ownership changes; the provenance card and our database log serial, service history, parts, and finish.

- How it works: Start a service ticket with serial and photos; we respond with next steps and timeframes, and we log the outcome for future owners.

Take-Back, Resale, and Circularity Metrics

- Programs: Trade-in and certified resale channels help keep Bravewood pieces in service and out of landfills.

- Metrics we publish: Repair rate, resale rate, and average years-in-service, reported annually.

- Why it matters: Furniture waste has surged in recent decades; building to repair and resell is a tangible antidote [1] [8] [9].

Fast Furniture vs. Heirloom: Durability, Waste, and True Cost

Fast furniture’s hidden cost shows up in cracked joints, swollen panels, and curbside days. Heirloom builds cost more upfront—but dramatically less per year of service, and they can be repaired, refinished, and resold.

Why Mass-Produced Pieces Fail Prematurely

Common failure modes we see in the shop:

- Cam-lock joints loosen under racking.

- Thin veneers chip; MDF swells with humidity and loses fastener grip.

- Screws strip out of particleboard; undersized hinges/screws migrate.

Process-focused QA content highlights why raw material control, proper fastening, and testing are essential—shortcuts age poorly [10].

The Waste Problem in Numbers

- Americans discard well over 10 million tons of furniture each year, a dramatic rise since 1960—trends documented by EPA and widely reported by major media [1] [8] [9].

- Why this matters: Fast replacement cycles compound landfill pressure; buying durable, repairable goods materially reduces waste intensity over a lifetime.

Lifecycle Cost and Carbon: Buy Once vs. Replace Often

A simple 30-year comparison (illustrative, not universal):

- Scenario A (Heirloom): Bravewood dining table: $3,800 upfront; annual maintenance (care kits/occasional touch-up): ~$30/year; 30-year TCO ≈ $3,800 + $900 ≈ $4,700 ($157/year).

- Scenario B (Fast furniture): $900 table replaced every ~6–8 years: assume four purchases over 30 years = $3,600; two paid deliveries/haul-aways ($150 each) = $300; mid-life repair or top replacement = $250; 30-year TCO ≈ $4,150 ($138/year) but with lower utility, higher failure risk, and landfill impact.

Factor in resale value (heirloom retains, fast furniture rarely does) and repairability (lower embodied carbon over time), and heirloom ownership often becomes the better total-value path, particularly beyond year 10. Use our calculator to adjust assumptions for your reality.

Interactive: Lifecycle Cost Calculator

- We provide a simple tool to model:

- Inputs: Upfront price, years-to-replacement (or life expectancy), maintenance, delivery/haul-away, resale value, and discount rate (optional).

- Outputs: Total 30-year cost and cost per year of service, with sensitivity sliders.

- Documentation: Default values include date-last-updated and a downloadable CSV of example scenarios for transparency.

How to Choose Furniture That Lasts Generations: A Field-Tested Checklist

You don’t need to be a woodworker to spot quality. Use these quick, respectful tests in-store or when reviewing detailed product photos.

Verify Materials and Joinery (In-Store or Online)

- Solid vs veneer/MDF: Look under tops and behind cases; solid boards show continuous end grain; veneers wrap over edges with a different core visible on undersides.

- Dovetails: Visible end-grain pins/tails at drawer corners—crisp, well-fitted, not just decorative caps.

- Frames: Mortise-and-tenon rails into legs; feel for racking resistance diagonally across the piece.

Independent consumer guides like This Old House offer simple visual checks that align with these practices [2].

Finish and Hardware Checks

- Finish: Even sheen, no sand-through on edges, no solvent odors lingering. On a sample, ask about ring/stain resistance and repair pathways.

- Slides/hinges: Brand markings, smooth action, no side play; soft-close where applicable. Check mount screws—proper pilot sizing and no stripped heads.

Moisture Meter How-To and Target Ranges

- Meter types: Pin and pinless both work; pin meters read depth where inserted; pinless scan the surface.

- How to measure: Take discreet readings on underside edges; avoid metal fasteners and finish artifacts. Look for 6–8% MC at receipt; home RH of 35–55% helps maintain equilibrium.

- Seasonal checks: Expect small, normal gaps or shifts across grain; your documentation explains what’s in-bounds.

Budgeting Smartly: Spend Once, Not Thrice

- Prioritize: Start with the pieces that take the most daily use (dining table, primary dresser, entry bench).

- Amortize: Divide the price by expected years-of-service; include likely maintenance. Use the calculator framework above.

- Motivation check: Consider the environmental and hassle costs of replacements; EPA waste figures are sobering context for choosing durable goods [1].

Printable: Buyer’s Inspection Checklist (PDF)

Our one-page checklist maps each line item (materials, joinery, MC, finish, hardware, repairability) to a cited principle so you can audit any brand with confidence. It includes QR codes to short how-to clips for wobble, drawer cycle, and finish spot tests.

Timeless Craftsmanship and Design: What Never Goes Out of Style

Timelessness is as much about restraint and honesty as it is about craft. We look to enduring movements like Shaker and Arts & Crafts for proportion and purpose—and we pair them with modern function.

Proportion and Honesty: The DNA of Timeless Forms

- Visual balance: Use calm proportions and alignments that feel inevitable rather than trendy.

- Honest materials: Let grain, joinery, and handwork show; avoid faux distressing that won’t age gracefully.

Design and craft organizations preserve and promote these fundamentals, offering a rich historical context for what endures [6].

Machine Precision Meets Hand-Finished Soul

- Where machines excel: CNC-precise joinery fits, consistent mortise spacing, and repeatable components.

- Where hands win: Final fitting, surface prep, eased edges, and touch-critical surfaces. Skilled handwork refines what machines begin, improving both look and feel over decades [5].

Patina-Friendly Finishes That Age Gracefully

- Film finishes: Highest day-one protection; repairs require skill and spot-blending.

- Oil/wax: Lower initial protection; fastest renewals and warm hand-feel.

We’re running long-horizon patina studies across common species/finishes to document scratch, heat, and spill behavior over time; meanwhile, trade testing provides practical renewal guidance [5].

Sustainably Sourced Wood, Verified

Responsible wood is durable by nature and responsible by design. We make verification easy and teach you how to check any maker’s claims.

FSC vs PEFC: What Each Means and How to Verify

- FSC and PEFC are the leading independent systems for forest stewardship and chain-of-custody certification. Consumers can confirm certificate IDs, scope, and validity directly on their portals [3] [4].

- Chain-of-custody: Ensures certified wood remains identified across each transfer. Ask for documents that link the certificate holder, your order, and the materials used.

Lacey Act and EUDR: What’s Changing in Wood Transparency

Regulations in major markets continue to elevate traceability and legality. Our sourcing documentation packet explains the data we collect and how we manage due diligence with suppliers to stay aligned with emerging rules.

Durable, Responsible Species Recommendations

- White oak: Durable, stable, widely available in responsibly managed North American forests; excellent for casegoods and tables.

- Hard maple: Extremely tough; ideal for tabletops and drawer sides.

- Walnut: Moderate hardness, beautiful patina; great for casegoods with the right finish expectations.

For consumer-friendly context on sustainable wood sourcing practices and tradeoffs, neutral guides can provide helpful overviews [12].

Best Heirloom-Quality Wooden Furniture Brands: How Bravewood Compares

We encourage transparent, criteria-based evaluation across brands. Use this rubric to score any maker—us included.

Comparison Criteria and Scoring Rubric

- Materials (weight 20%): Solid hardwoods, species disclosure, grain orientation on long spans.

- Joinery (weight 25%): Mortise-and-tenon, dovetails, panel construction; visible proof.

- Finish (weight 15%): Chemistry matched to use-case, renewability, documented performance.

- Hardware (weight 10%): Brand, cycle/load ratings, part numbers.

- Repairability (weight 15%): Access, standardized parts, documentation, finish renewability.

- Sustainability (weight 10%): FSC/PEFC documentation and chain-of-custody transparency.

- Warranty/Service (weight 5%): Transferability, responsiveness, service records.

Provide sources and dates for each claim you score.

Brand Snapshots: Stickley, MAVIN, The Joinery, Daniel’s Amish (Overview)

A fair snapshot typically includes: solid species used, joinery norms, finish systems available, warranty terms and exclusions, lead time ranges, and customization scope—sourced from official catalogs/spec pages and dated notes. Use the rubric above to compare apples to apples, and always request proof (joinery photos, finish specs, hardware part numbers) before finalizing a purchase.

Where Bravewood Excels

- MC transparency: We publish 6–8% shipment targets with logs.

- Test evidence: Racking and cycle test clips with summarized methods.

- Repairability Index: Clear scoring with rationale and spare-part pathways.

- Warranty transferability: Provenance card and service-history database.

- Circularity: Take-back/resale and annual repair/resale KPIs.

Care and Maintenance for Generational Longevity

A little care dramatically extends service life and keeps finishes looking their best. We provide a maintenance calendar and guidelines with every piece.

Humidity and Placement Guidelines

- RH target: Maintain 35–55% indoors; monitor with a reliable hygrometer.

- Placement: Keep pieces away from direct heat vents/radiators and prolonged direct sunlight; use felt or rubber feet to isolate from damp floors.

- Acclimation: After delivery, let pieces settle for 24–48 hours before heavy loading; confirm base level before tightening any fasteners.

A delivery-day checklist includes MC readings, hardware checks, and surface inspection; we repeat it during annual service calls.

Cleaning, Protection, and Annual Checks

- Cleaners: Use product-neutral, finish-safe cleaners; avoid silicone polishes that complicate future refinishes.

- Protection: Coasters, trivets, and pads prevent heat/moisture rings; felt under accessories prevents scratches.

- Annual: Inspect and re-torque accessible fasteners, check slides/hinges for smoothness, re-wax or refresh oil on applicable finishes, and touch up glides.

When to Refinish or Repair—and How

- Spot repair vs refinish: Small scratches and water marks on oil/wax finishes are often fixable without stripping; deep film damage on tabletops may justify a professional refinish.

- Decision tree: Identify finish type, damage extent, and location; consult your provenance card for the exact finish system and follow our repair SOPs. Our service team can advise, quote, or arrange in-shop work with documented before/after photos.

For general expectations on household component lifespans and maintenance cadence, neutral charts are a useful starting point [11].

FAQs: Your Most Asked Questions, Answered

Who is Bravewood and what makes Bravewood pieces heirloom-quality?

We’re a transparency-first workshop. Our Heirloom Standard codifies what “heirloom” means: solid FSC/PEFC–verified hardwoods, 6–8% MC at shipment, movement-tolerant joinery (mortise-and-tenon, dovetails), finishes matched to use and repairability, premium hardware, documented QC, and lifelong service. Independent craft guidance aligns with these fundamentals [2] [3] [4] [5].

Which hardwoods does Bravewood use and where are they sourced?

Our core species are white oak, hard maple, and walnut—sourced from responsibly managed North American forests with FSC/PEFC documentation and intact chain-of-custody records available for each job file [3] [4].

What joinery and finishes are used, and how do they impact longevity?

Mortise-and-tenon frames and dovetailed drawers provide exceptional racking resistance and durability. For finishes, we spec conversion/catalyzed varnishes for high-wear tops and oil/wax for tactile pieces that benefit from easy renewals. Craft testing and practice support these choices [2] [5].

What warranties or repair services does Bravewood offer?

We back structural integrity with a transferable lifetime warranty, and we maintain a provenance card and service-history record per piece. Start a service ticket with the serial number and photos; we respond with next steps and timelines, then log the work for future owners.

How should I care for a Bravewood piece so it lasts generations?

Maintain 35–55% RH; clean with finish-safe products; protect tops with coasters/pads; perform an annual fastener and glide check; and follow your maintenance calendar. This approach aligns with long-standing home care guidance [11].

How can I verify solid hardwood and quality joinery in-store?

Look for continuous end grain on edges/undersides, not veneer seams; check for dovetailed drawers and mortise-and-tenon frames; perform a gentle wobble/rack check; and ask for hardware part numbers and finish specs. Simple consumer checks from trusted sources mirror these steps [2].

Which finishes last the longest and can be renewed?

Film finishes offer top protection for heavy-use surfaces; oil/wax systems are easiest to renew in place. Choose based on use-case and your maintenance preferences; craft testing explains the tradeoffs [5].

Is durable furniture more cost-effective over time?

Often yes—especially beyond the 10-year mark. Use our calculator to compare upfront price, expected life, maintenance, deliveries/haul-away, and resale value. Waste statistics reinforce the value of durable, repairable pieces [1].

How do I responsibly dispose of or donate old furniture?

Clean, repair minor issues, and document dimensions and materials. Consider consignment, local donation networks, or certified resale where available. Bravewood offers take-back/resale for our pieces with documented outcomes.

Lead times, customization, and pricing for handcrafted pieces?

Expect collaborative design steps, sample approvals, and lead times that reflect finishing and curing schedules. Customization, species choice, and finish complexity are the main price/lead drivers; we publish current averages and keep you updated during production. For industry context, artisan workshops commonly follow similar stages.

Conclusion

Heirloom shouldn’t be a marketing flourish—it should be a measurable, test-backed promise. Bravewood’s Heirloom Standard turns that promise into proof: certified hardwoods, 6–8% moisture control, structural joinery, performance-matched finishes, documented QC, and lifelong service—with a Repairability Index, buyer’s inspection checklist, lifecycle cost calculator, and brand rubric you can use anywhere. Buy once, for generations.

Call to action: Download the Bravewood Heirloom Standard and Buyer’s Inspection Kit, then book a design consult or request finish/wood samples. Prefer to validate in person? Schedule a showroom visit or virtual shop tour.

Disclaimer

Comparisons and brand specifications are based on publicly available information as of publication and may change. Warranty terms are subject to Bravewood’s official policy documents. Environmental impact and lifecycle cost figures are estimates with stated assumptions. Third-party trademarks are property of their respective owners. Product availability, pricing, and lead times vary.

References

- United States Environmental Protection Agency (EPA). (N.D.). Facts and Figures about Materials, Waste and Recycling. Retrieved from https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling

- This Old House. (N.D.). How Heirloom Furniture Is Built. Retrieved from https://www.thisoldhouse.com/furniture/21018437/how-heirloom-furniture-is-built

- Forest Stewardship Council (FSC). (N.D.). Certification. Retrieved from https://us.fsc.org/en-us/certification

- Programme for the Endorsement of Forest Certification (PEFC). (N.D.). Home/Certification Resources. Retrieved from https://www.pefc.org/

- Fine Woodworking (Taunton Press). (N.D.). Techniques and Tests on Joinery and Finishes. Retrieved from https://www.finewoodworking.com/

- The Furniture Society. (N.D.). About/Resources. Retrieved from https://furnituresociety.org/

- InterNACHI. (N.D.). Life Expectancy of Home Components. Retrieved from https://www.nachi.org/life-expectancy.htm

- Green, P. (2022). Fast Furniture Is Cheap. And Americans Are Throwing It in the Trash. The New York Times. Retrieved from https://www.nytimes.com/2022/10/31/realestate/fast-furniture-clogged-landfills.html

- Rybakoff, D. (2022). ‘Fast Furniture’ is Bad for the Planet. CNN Style. Retrieved from https://www.cnn.com/style/article/fast-furniture-problem-for-our-planet

- InTouch Quality. (2019). Wooden Furniture Quality Assurance: Key Challenges and Solutions. Retrieved from https://www.intouch-quality.com/blog/wooden-furniture-quality-assurance-key-challenges-and-solutions

- This Old House. (N.D.). How Long Stuff Lasts. Retrieved from https://www.thisoldhouse.com/21015248/how-long-stuff-lasts

- Kebony. (N.D.). The Importance of Sustainable Wood Sourcing: A Comprehensive Guide. Retrieved from https://us.kebony.com/blog/sustainability/the-importance-of-sustainable-wood-sourcing-a-comprehensive-guide/