Introduction

If you’re tired of short product lifespans, vague warranty fine print, and eco-claims that don’t stand up to scrutiny, you’re not alone. Bravewood exists for people who want to buy it once—and enjoy it for decades. Our “Designed to Stay” system pairs sustainable design with durable quality craftsmanship, repairability, and transparent specifications you can verify. Throughout this guide, you’ll find proof, not promises: materials provenance, finish test method references, joinery standards, and cost-per-year tools that help you choose, customize, and care for sustainable investment pieces built to last. Here’s what we’ll cover: brand clarity, durability-by-design, verifiable sustainability, investment math, a practical decision framework, how we beat obsolescence and waste, and the aftercare and support that keep Bravewood pieces in service for decades.

- Introduction

- What Bravewood Makes and Why It’s Designed to Stay

- Durability by Design: Materials, Joinery, and Quality Control

- Finish Systems and Indoor Air Quality: Beauty Built to Last

- Sustainability You Can Verify: Materials, LCA, and Certifications

- Investment Value and Ownership ROI: Cost-Per-Year, Warranty, and Resale

- Purposeful Purchasing: A Decision Framework for Long-Lasting Products

- Outsmarting Planned Obsolescence and Cutting Waste

- Care, Repair, Delivery, and Customization: Support for Decades

- Frequently Asked Questions

- What does Bravewood make and where is it based?

- How are Bravewood finishes applied and how durable are they?

- What woods and materials are used and are they sustainably sourced?

- Do you offer custom sizing, design collaboration, and worldwide shipping?

- What warranty, maintenance, and repair support are provided?

- How do durability and repairability fit into sustainability?

- How do I calculate whether a higher-priced item is worth it over time?

- Conclusion

- Disclaimer

- References

What Bravewood Makes and Why It’s Designed to Stay

We build solid hardwood furniture—tables, desks, benches, seating, and storage—one piece at a time. That small-batch focus lets us obsess over the details that matter for longevity: traceable materials, time-tested joinery, repairable finishes, rigorous quality checks, and service that never disappears after delivery. “Designed to Stay” is both an ethos and an engineering standard: every design decision is filtered through sustainability, durability, and lifetime support.

E-E-A-T commitments we uphold:

- Workshops staffed by seasoned craftspeople; methods and build logs are documented for transparency.

- A photographed QA checklist applied before crating and shipping.

- Verifiable third-party reviews via independent platforms (with dates and order IDs when provided).

- A plain-language, limited-lifetime warranty that spells out what’s covered and how to get help.

Bravewood at a Glance: Products, Place, and Philosophy

- What we make: Solid hardwood tables and desks, dining and occasional seating, and storage built to be refinished and repaired—not replaced.

- How we build: Slow, small-batch production, stable lumber preparation, joinery that respects wood movement, and finish systems selected for durability and indoor air quality.

- How we ship: Custom crating, shock and tilt indicators, and pre-shipment QA checks designed to safeguard heirloom-grade furniture in transit.

- Brand clarity: Bravewood is a furniture maker focused on sustainable, durable investment pieces. If you’ve encountered similarly named entities, consider this your disambiguation note—you’re in the right place for handcrafted, “Designed to Stay” furniture.

- Our philosophy: Designed to Stay means engineering for decades of use; choosing ethical materials and low-emission finishes; and backing every piece with clear warranty, parts availability, and a repair/refinish pathway.

The “Designed to Stay” System

Think of your furniture’s life as a loop, not a line:

- Responsible sourcing: Ethical, traceable wood and low-emission finish systems (FSC and GREENGUARD guidance where applicable) 12.

- Engineered construction: Joinery that allows seasonal movement, moisture targets at assembly, and hardware that can be tightened or replaced over time.

- Durable, repairable finishes: Finishes selected for abrasion, chemical, and heat resistance, with repair/refinish options outlined in care guides (ASTM/ISO test methods referenced where applicable) 89.

- Rigorous quality assurance: Documented checkpoints on moisture, flatness, joinery, finish integrity, and final inspection prior to packaging.

- Safe delivery: Purpose-built packaging and handling protocols for global shipping.

- Lifetime support: Parts availability timelines, touch-up guidance, and professional refinishing services that extend service life and support resale.

Durability by Design: Materials, Joinery, and Quality Control

Durability isn’t an accident; it’s a system. Below is how we design investment furniture that resists a short product lifespan and meets recognized performance ideas (including applicable ASTM furniture and finish test methods) 789.

Material Selection: Stable, Traceable Hardwoods

- Species and stability: We select hardwoods for dimensional stability, hardness, and repairability. Species are paired with joinery and construction details appropriate to the span and application (for example, large tabletops engineered with movement allowances).

- Lumber prep: Graded, kiln-dried lumber is acclimated to the shop and again to the assembly environment to minimize internal stresses that cause warping or cracking. Best practices often target equilibrium moisture content ranges at assembly aligned to the installation climate.

- Traceability: Where applicable, we source and document FSC-certified wood and maintain chain-of-custody records so claims can be verified 1.

- What you can verify: Our spec sheets disclose species, source categories (e.g., FSC-certified, reclaimed), finish families, and care requirements.

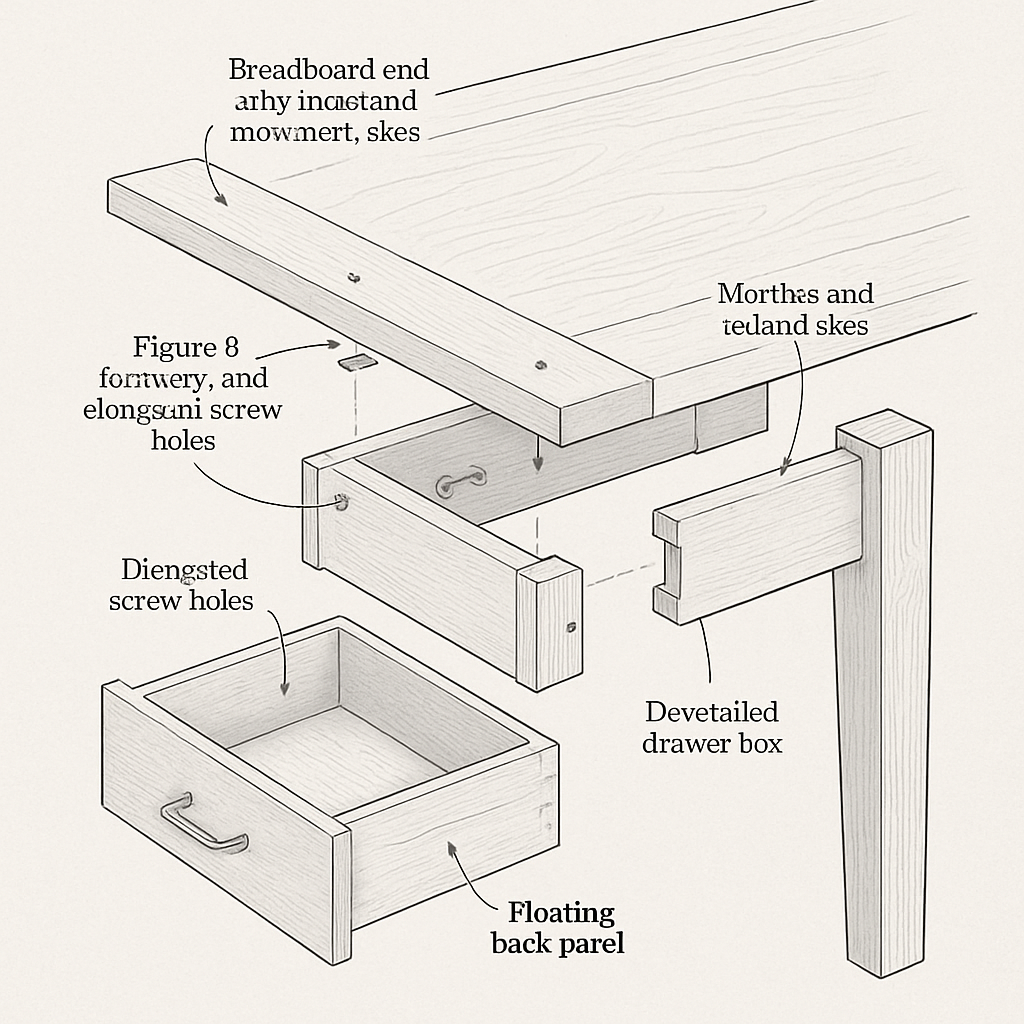

Joinery That Respects Wood Movement

- Movement-aware design: Solid wood expands and contracts across the grain. We use joinery and construction details that accommodate that reality—mortise-and-tenon frames, dovetailed drawers, floating panels, breadboard ends with concealed movement slots, elongated screw holes, and figure-8 or z-clips for tops.

- Why it matters: These details reduce stress concentrations, prevent splits, and keep joints tight for decades.

What to look for:

- Tops attached with hardware that allows expansion.

- Drawer boxes with interlocking joinery (e.g., dovetails).

- Carcass construction with back panels that reinforce racking resistance while allowing seasonal movement.

Moisture Targets, Adhesives, and Hardware

- Moisture at assembly: We build when the workpieces and shop environment have equilibrated to the target range for the destination climate, reducing post-installation movement.

- Adhesives: Wood adhesives are selected for bond strength, open time, and environmental performance. When available, we reference supplier technical data (bond strength, temperature range, and emissions). Low-emission formulations can be verified via programs like UL GREENGUARD where applicable 2.

- Hardware: Through-bolted stretchers, threaded inserts, locking fasteners, and replaceable glides extend service life by enabling maintenance and repair.

- QC checkpoints: Pre-shipment checks include joint integrity, top flatness/levelness, hardware torque, finish cure verification, and packaging integrity. Where relevant, category performance references draw on established standards (e.g., ASTM furniture stability for storage units) 7.

Finish Systems and Indoor Air Quality: Beauty Built to Last

Durable finishes protect wood, simplify care, and influence indoor air quality. We evaluate finish systems across three dimensions: performance, emissions/safety, and repairability.

Finish Performance: The Data That Matters

What to ask for on a finish technical data sheet (TDS):

- Abrasion resistance test method and results (for example, ASTM D4060 Taber abrasion cycles) 8.

- Chemical/stain resistance with test methods like ASTM D1308 (household chemicals) 9.

- Heat resistance/print resistance, plus cure schedule and full hardness window.

How to interpret it:

- Abrasion: Higher cycles typically indicate more scratch resistance.

- Chemical: Look for resistance to common agents (water, alcohol, coffee, oils).

- Heat: Tolerance to brief exposure to hot plates or mugs reduces white-ring risk.

Practical tip: High-performance film finishes can excel in abrasion/chemical tests, while hardwax oils are more easily spot-repaired. Choose based on use-case and willingness to perform minor maintenance.

Emissions and Safety: Breathing Easy Indoors

- Low-VOC vs low-emission: VOC content is one metric; total emissions over time is another. Programs like UL GREENGUARD evaluate emissions to defined thresholds for indoor air quality 2.

- Safer maintenance: For routine cleaning, the EPA Safer Choice program identifies products that meet rigorous human and environmental health criteria 11.

Finish Care and Repairability

Routine care:

- Dust with soft cloths; clean with pH-neutral, Safer Choice–recognized products 11.

- Use trivets/soft pads; blot spills promptly.

Touch-ups and refresh:

- Micro-scratch blending and spot repairs depend on finish system; we provide finish-specific guides.

- Full refinishing: Our refinishing service restores protection and appearance without discarding the piece, preserving embedded carbon and craftsmanship.

Sustainability You Can Verify: Materials, LCA, and Certifications

Sustainable design isn’t a label—it’s a system you can check. We align to recognized methods and frameworks, publish documentation where applicable, and prioritize durability and repairability because they meaningfully reduce environmental impact.

Ethical, Durable Materials and How to Verify Them

- Timber: FSC chain-of-custody programs help verify responsibly managed forests and tracked supply chains 1.

- Alternatives: Reclaimed wood, recycled metals, and rapidly renewable materials (like bamboo) are considered where they make sense structurally and aesthetically.

- Finishes/adhesives: Prefer low-emission systems; GREENGUARD or similar certifications provide third-party verification 2.

Verification steps you can take:

- Ask for certificate numbers (e.g., FSC CoC) and renewal dates, plus supplier names.

- Request finish TDS and, where applicable, emissions certificates or listings.

LCA in Practice: Durability as a Sustainability Lever

- The method: Life Cycle Assessment (LCA) per ISO 14040/14044 evaluates environmental impacts from raw materials to end-of-life 34.

- Why longevity matters: Extending service life spreads the “upfront” manufacturing impacts across more years and fewer replacements. In a simple model:

- Circular design tie-in: Designing for repair, refurbishment, and safe materials aligns with circular economy principles touted by the Ellen MacArthur Foundation and supports SDG 12 goals on responsible consumption and production 56.

Certifications, Simplified: What Matters for Furniture

- Wood: FSC (vs. PEFC in some regions)—forest management and chain-of-custody verification; ensures traceability rather than guaranteeing end-product durability 1.

- Emissions: UL GREENGUARD—tests products for low chemical emissions to improved indoor air quality; stronger than generic “low-VOC” claims 2.

- Circularity/safe materials: Cradle to Cradle Certified assesses material health, circular design, renewable energy, water stewardship, and social fairness at the product level 16.

How to verify:

- Ask for certificate numbers/links and scope (which products, which sites).

- Confirm current status on the certifier’s site before purchase.

Investment Value and Ownership ROI: Cost-Per-Year, Warranty, and Resale

True investment pieces combine durability, serviceability, and timeless design. The value is measurable.

What Qualifies as a Furniture Investment Piece?

- Core criteria:

- Durable materials with stable, traceable sourcing.

- Movement-conscious joinery and construction.

- Verifiable finish and emissions data (TDS, test methods, and if applicable, GREENGUARD) 289.

- Repairable design with a documented parts and service pathway.

- Clear warranty and parts availability timelines.

- Timeless proportions and details that resist stylistic obsolescence.

- Behavioral proof: The Buy-It-For-Life community champions products that remain in use for decades, emphasizing reliability, repairability, and service support 18.

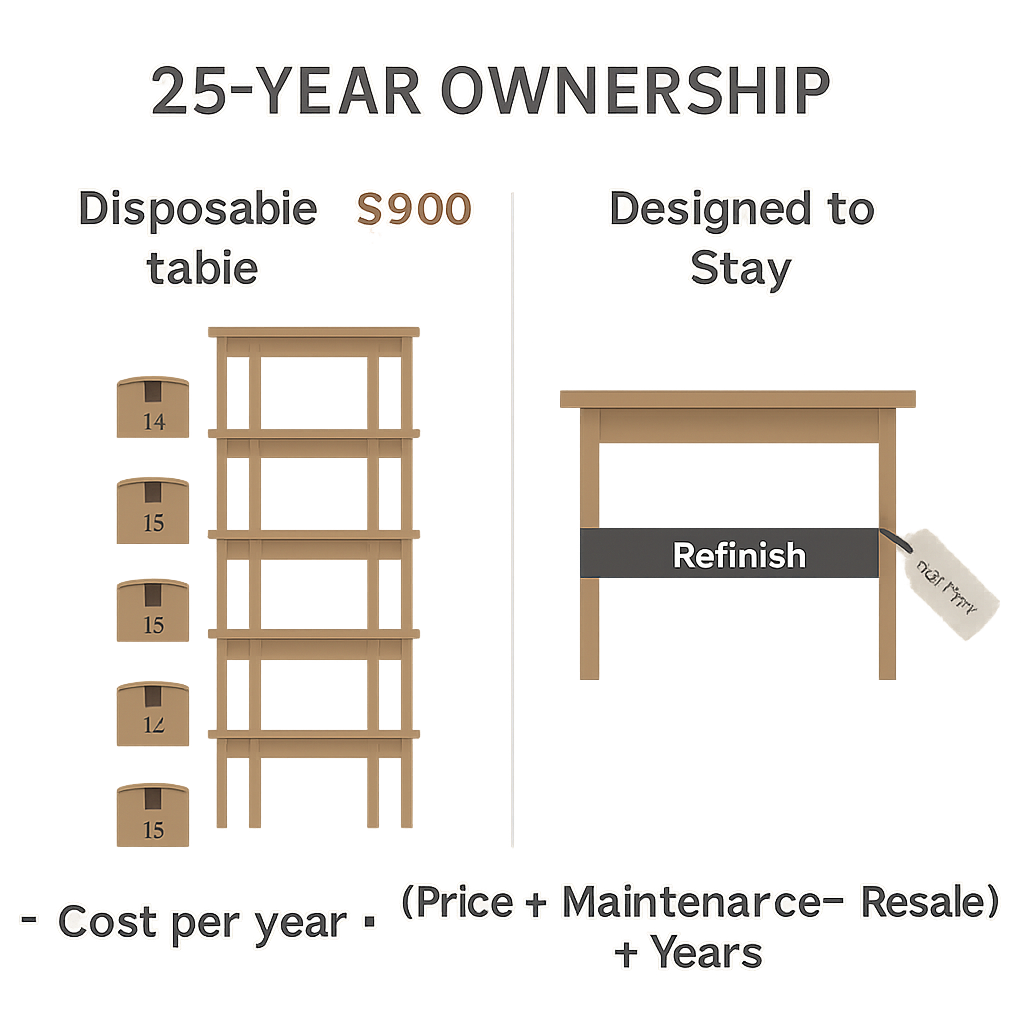

Cost-Per-Year and Total Cost of Ownership

Formula:

- Cost per year = (Purchase price + Cumulative maintenance – Expected resale) ÷ Years of use.

Worked example (illustrative):

- Disposable option: $800 table lasting 5 years, negligible resale, basic care = ($800 × 5 replacements) ÷ 25 years = $160/year.

- Designed to Stay: $3,000 table lasting 25 years, $350 total care (pads, cleaner, one professional top refresh), $600 resale = ($3,000 + $350 – $600) ÷ 25 ≈ $110/year.

Assumptions disclosed:

- Comparable function and satisfaction; steady usage; professional refinish once; conservative resale.

- Your results vary by use environment, care, market demand, and maintenance choices.

- For procurement teams: Use TCO ranges to stress-test budgets and replacement assumptions; document maintenance standards and refinish intervals to preserve asset value.

Category Checklists: What to Inspect Before You Buy

Use these Buy-It-For-Life checklists to evaluate remotely or in person. Where applicable, request references to recognized performance standards (e.g., ASTM stability for storage) 7.

Tables and Desks

- Top and base: Stable hardwood species; wide tops engineered with breadboard ends or equivalent movement allowances.

- Attachment: Elongated holes/slots, figure-8s, or z-clips for top fastening.

- Flatness/level: QC checks documented; adjustable levelers for uneven floors.

- Finish: TDS referencing abrasion/chemical/heat test methods (e.g., ASTM D4060, D1308) 89.

- Moisture targets: Disclosed acclimation and assembly targets appropriate to destination climate.

Seating

- Joinery: Mortise-and-tenon joints, corner blocks, through-tenons where appropriate.

- Load and racking resistance: Documented construction details; ask for any internal testing notes.

- Glides and components: Replaceable glides/foot caps; screws and bolts accessible for tightening.

- Finish: Abrasion-resistant and repairable in high-contact zones.

Storage

- Carcass: Dadoes or dovetails; robust back panel integration for racking resistance.

- Drawers: Dovetailed boxes; quality slides with rated loads.

- Anti-tip: Stability and anti-tip provisions for tall units; request adherence to applicable safety specifications (e.g., ASTM F2057 for clothing storage units) 7.

- Finish: High-abrasion resistance on handles and frequently touched edges.

Warranty, Parts, and Resale Value

- Warranty clarity: A limited-lifetime warranty typically covers defects in materials and workmanship under normal residential use; excludes misuse, improper humidity control, and abnormal exposure. We publish a matrix by product line, including exclusions and claim steps.

- Parts availability: Documented timelines for hardware, glides, and finish touch-up materials support decades of service.

- Provenance and resale: Each piece can be paired with a provenance card/QR documenting build date, primary materials, finish family, and maintenance history—assets that can increase resale confidence and value.

Purposeful Purchasing: A Decision Framework for Long-Lasting Products

If you want to cut waste and maximize value, adopt a pre-purchase discipline. It works equally well for households and organizations.

The Pre-Purchase Checklist

Ask every seller:

- Materials and sourcing

- Which wood species? Any FSC-certified or reclaimed options (certificate numbers and supplier names if applicable) 1.

- Construction

- How is seasonal movement handled (joinery, hardware, slots)? What are the moisture targets at assembly?

- Finish and emissions

- Serviceability

- What parts are user-replaceable? What’s the parts availability timeline?

- Touch-up and full refinish pathways—DIY vs. professional options and costs.

- Warranty and logistics

- Warranty length, coverage, exclusions. Claim process and response time.

- Packaging standards, shock/tilt indicators, and shipping insurance.

Sample email template:

“Hello [Maker], I’m considering [Product]. Could you share: (1) species and sourcing details (FSC CoC if applicable), (2) joinery/movement allowances, (3) finish TDS with any ASTM/ISO test method references, (4) emissions certifications (e.g., GREENGUARD), (5) warranty terms and parts availability timelines, and (6) packaging/shipping safeguards? Thank you.”

Scoring rubric (pass/fail tendencies):

- Transparent specs and verifiable certifications: pass.

- Movement-aware construction with documented QC: pass.

- Repair/refinish pathway with parts timeline: pass.

- Vague materials, no test methods, unclear warranty: fail.

Embedding Durability in Organizational Procurement

- Specification language (examples):

- Materials: “Primary timber shall be FSC-certified or documented reclaimed, with certificate numbers included in submittals” 1.

- Construction: “Solid wood assemblies shall include movement allowances; provide shop drawings showing slotting/attachment details.”

- Finish: “Submit TDS referencing abrasion and chemical resistance test methods (ASTM D4060, D1308 or equivalent).” 89

- Emissions: “If available, provide product-level GREENGUARD or equivalent emissions certification” 2.

- Support: “Provide warranty matrix, parts availability timelines (minimum 10 years), and repair/refinish procedures.”

- Circular procurement alignment: Reference circular design principles to prioritize longevity, repairability, and verified materials 65.

Outsmarting Planned Obsolescence and Cutting Waste

Planned obsolescence is the practice of designing products to wear out prematurely, go out of style quickly, or become unusable due to lack of parts/service. It drives waste and costs consumers dearly 121314. Bravewood is designed as the antithesis.

What Planned Obsolescence Looks Like in Furniture

- Technical obsolescence: Weak joints, undersized hardware, or finishes that fail under normal use.

- Stylistic obsolescence: Trend-chasing silhouettes and finishes that look dated fast.

- Systemic obsolescence: No parts, no repair guidance, and no one to call years later.

Buyer red flags:

- No movement allowances in solid tops.

- Particleboard in high-stress joinery zones for “solid wood” products.

- Vague warranties and no parts timelines.

- No finish data or care instructions.

Context and history: Reputable explainers and academic discussions trace obsolescence from lightbulbs to electronics, with legal/policy responses and right-to-repair movements highlighting its harms 12131714.

The Waste We Avoid When Products Last

- Macro picture: UN SDG 12 calls for responsible consumption and production, citing huge global waste challenges (including 931 million tons of food waste annually) and the need to curb wasteful consumption through better product and policy choices 5.

- Consumption trends: Analyses by institutions such as the Columbia Climate School highlight how changing lifestyles have driven waste higher over time—and why extending product lifespans is a powerful lever 15.

- Furniture impact model (illustrative):

- Replacing a 5-year piece 5 times vs. maintaining a 25-year piece can avoid multiple manufacturing and freight cycles. Even with one professional refinish mid-life, the cumulative impacts are typically far lower for the long-life path (assumptions: comparable function, responsible end-of-life, and localized service where possible) 345.

Our “No Obsolescence” pledge:

- Documented build methods, finish data references, and care guides.

- Warranty and parts timelines published for each product line.

- Repair/refinish services and takeback/refurbish options wherever feasible.

- Continued access to spec sheets and support documentation over time.

Care, Repair, Delivery, and Customization: Support for Decades

Your furniture’s longest life comes from thoughtful care and predictable support. We design for both.

Maintenance Calendar and Care Kits

Quarterly:

- Inspect fasteners and glides for tightness and wear.

- Dust; clean with pH-neutral, Safer Choice–recognized cleaners 11.

Seasonally:

- Verify humidity stays in a recommended range for solid wood (use a hygrometer).

- Refresh protective pads; rotate surfaces exposed to strong sunlight.

Annually:

- Conduct a deep clean; assess for touch-ups per finish guide.

- Consider a professional top refresh for heavy-use dining/work surfaces when warranted.

Care kits:

- Include cleaner, touch-up materials specific to the finish family, glide replacements, and felt or cork pads—shipped on a subscription or as-needed basis.

Repairs, Refinishing, and Parts Availability

- Touch-ups: Finish-specific spot repairs for micro-scratches and edge wear.

- Structural service: Tightening joints and replacing wear components (glides, bolts) to prevent progressive damage.

- Refinishing: Professional refinish restores protection and appearance, preserving embodied materials and craftsmanship.

- Parts timelines: We publish availability expectations for core components and finish touch-up materials so owners can plan decades ahead.

Safe Shipping and Customization with Integrity

- Packaging and shipping:

- Custom crating, corner/edge protection, moisture barriers as needed, and shock/tilt indicators—plus documented pre-ship QC with photos.

- Customization with integrity:

- We’ll adjust dimensions and details within boundaries that preserve structural allowances, stability, and certification scopes (e.g., maintaining movement slots, compatible finishes, and material traceability). The goal is to fit your space without compromising longevity or sustainability claims.

Frequently Asked Questions

What does Bravewood make and where is it based?

We are a small-batch furniture maker specializing in solid hardwood tables, seating, and storage designed for decades of use. Our focus is durable, repairable construction and verifiable sustainability for true investment pieces.

How are Bravewood finishes applied and how durable are they?

We use finish systems evaluated for abrasion, chemical, and heat resistance, and we share the supplier test methods (e.g., ASTM D4060 Taber abrasion; ASTM D1308 household chemical resistance) to clarify real-world performance 89. We also provide care guidance and, where applicable, emissions certification references such as GREENGUARD listings 2.

What woods and materials are used and are they sustainably sourced?

We prioritize stable hardwoods that are traceable, repairable, and appropriate for the application. Where applicable, we source FSC-certified timber and maintain chain-of-custody documentation you can verify 1. Reclaimed and recycled materials are used where they fit the structural and aesthetic brief.

Do you offer custom sizing, design collaboration, and worldwide shipping?

Yes. We collaborate on dimensions and details within engineering and sustainability constraints (movement allowances, materials traceability, finish compatibility). We ship worldwide using custom crating and damage-prevention checks designed for heirloom-grade furniture.

What warranty, maintenance, and repair support are provided?

Our limited-lifetime warranty covers defects in materials and workmanship under normal residential use. We publish parts availability timelines, provide care kits and documentation, and offer professional repair/refinish services to extend life and preserve value.

How do durability and repairability fit into sustainability?

Durability reduces replacement frequency and total lifecycle impacts; repairability and refurbishment keep products in service longer—key elements in LCA logic (ISO 14040/44) and circular economy principles aligned with UN SDG 12 3456.

How do I calculate whether a higher-priced item is worth it over time?

Use cost per year: (Purchase price + Maintenance – Expected resale) ÷ Years of use. Compare a long-life piece to multiple disposable replacements. Disclose your assumptions about care, resale, and usage to get a realistic comparison.

Conclusion

Proof, not promises—that’s the heart of Bravewood’s “Designed to Stay” philosophy. By pairing verifiable sustainability (traceable materials, emissions documentation, and circular design) with category-leading durability (movement-aware joinery, reliable finishes, and rigorous QA), plus lifetime support and clear warranties, we help you outsmart obsolescence, reduce waste, and maximize lifetime value. Ready to go deeper? Explore Bravewood’s Sustainable Investment Pieces, download the spec sheets and maintenance calendar, and request a personalized TCO comparison and customization consult.

Disclaimer

Specifications, certifications, test data, and availability may change. Environmental impact estimates are modeled; real-world results vary. This article is informational and not financial or legal advice.

References

- Forest Stewardship Council. (N.D.). Chain of Custody Certification.

- UL Solutions. (N.D.). UL GREENGUARD Certification Program.

- International Organization for Standardization. (2006). ISO 14040: Environmental management — Life cycle assessment — Principles and framework.

- International Organization for Standardization. (2006). ISO 14044: Environmental management — Life cycle assessment — Requirements and guidelines.

- United Nations. (N.D.). Sustainable consumption and production (SDG 12).

- Ellen MacArthur Foundation. (N.D.). Circular Design.

- ASTM International. (2023). ASTM F2057-23: Standard Consumer Safety Specification for Clothing Storage Units.

- ASTM International. (N.D.). ASTM D4060: Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser.

- ASTM International. (N.D.). ASTM D1308: Standard Test Method for Effect of Household Chemicals on Clear and Pigmented Organic Finishes.

- Consumer Reports. (N.D.). Research & Testing at Consumer Reports.

- U.S. Environmental Protection Agency. (N.D.). Safer Choice.

- Wikipedia. (N.D.). Planned obsolescence.

- Iberdrola. (N.D.). Planned obsolescence: what it is and why it’s a problem.

- Population Matters. (2024). From lightbulbs to smartphones: the practice of planned obsolescence.

- Columbia Climate School. (2019). How Our Consumption and Waste Impact the Environment.

- Cradle to Cradle Products Innovation Institute. (N.D.). Cradle to Cradle Certified — Product Certification.

- Repair.org. (N.D.). Stand Up for Your Right to Repair.

- American Marketing Association. (2021). Rise of the Buy-It-For-Lifers.