Introduction

Most home goods look beautiful on delivery day—but too many are short-lived products that loosen, warp, or wear out long before they should. Shoppers face marketing fluff, brand-name confusion, unclear warranties, and almost no way to verify durability online. Bravewood craftsmanship was created to solve that. We unite artisan heritage with transparent, test-backed build standards and a Generations Guarantee that prioritizes timeless durability, repairability, and lifelong service. In this guide, we define Bravewood craftsmanship, detail the materials, joinery, and finish performance behind our Build-to-Last Standard, outline our Generations Guarantee and provenance program, share a practical buyer’s durability checklist and lifecycle cost approach vs. mass-produced alternatives, and present how your purchase helps preserve endangered craft techniques for the next generation.

- Introduction

- What Is Bravewood Craftsmanship? Defining Artisan Heritage and Timeless Durability

- Materials and Sourcing: Woods, Moisture, and Finish Chemistry

- Joinery and Construction: Heritage Craftsmanship Techniques Built to Last

- The Bravewood Build-to-Last Standard: Measurable Durability You Can Verify

- Generations Guarantee: Lifetime Repair, Refurbish, and Transferable Provenance

- Care and Maintenance: How to Ensure Timeless Durability

- Buyer’s Toolkit: Durability Checklist and Lifecycle Cost vs. Mass-Produced Alternatives

- Preserving Artisan Heritage: Apprenticeships, Endangered Techniques, and Your Impact

- Brand Provenance and Authentication: Verifying the Real Bravewood

- Owner Stories: 1-, 5-, and 10-Year Performance Case Studies

- Conclusion

- Disclaimer

- References

What Is Bravewood Craftsmanship? Defining Artisan Heritage and Timeless Durability

Bravewood craftsmanship is the marriage of heritage techniques, measurable durability, and generational service. Where mass-produced alternatives optimize speed and unit cost, our workshop optimizes strength, stability, repairability, and provenance. Each piece is built with responsibly sourced hardwoods, controlled moisture content, time-tested joinery (like through mortise-and-tenon and dovetails), and finishes selected for performance and repairability over decades—not just showroom gloss. We document every build stage, sign and serialize each piece, and maintain an owner registry so provenance and service history remain intact for generations.

In an era of lookalikes and “factory handmade” claims, Bravewood’s difference is radical transparency: we publish build standards (wood species, moisture tolerances, joinery, finish chemistry), release QA snapshots from the shop, and provide a lifetime care roadmap. If you’re new to heirloom-quality craftsmanship, traditional best practices—solid joinery, appropriate species, movement-aware construction, reparable finishes—are the proven foundation for enduring furniture [1].

Where Bravewood Pieces Are Made and Who the Artisans Are

Our work is built in a dedicated Bravewood workshop by a small team of master craftspersons and apprentices. The team’s skills draw from documented lineages—mentors trained in heritage craftsmanship techniques pass on methods like hand-cut dovetails, wedged tenons, and traditional inlay. To honor artisan heritage, we emphasize real, hands-on transmission: apprentices complete a structured curriculum, skills are assessed at each milestone, and every apprentice pairs with a master for technique-specific mentoring.

What this looks like for you:

- Maker profiles: Each project references the specific artisans involved and their training lineages.

- Build diaries: Photo documentation at key milestones (rough mill, moisture checks, dry fit, glue-up, finish, final inspection).

- Real homes, real time: With owner permission, we include dated, geotagged installation images and testimonials to validate longevity in the wild.

How We Differ from Mass-Produced Alternatives

Mass-market builds often rely on thin veneers over unstable cores, weak fasteners, high-VOC finishes, and non-serviceable parts—choices that can lower initial price but increase total cost of ownership. Bravewood’s process favors solid joinery, dimensional-stability allowances, reparable finishes, and ready access to service parts. We also disclose our teardown methodology for side-by-side comparisons and our assumptions for lifecycle cost: initial price, expected lifespan, maintenance/refinish intervals, repair probabilities, and resale value.

- Comparative testing authority: Consumer Reports is a widely recognized authority on comparative testing and durability context for consumer goods [2].

- Planned obsolescence: Many categories suffer from contrived durability and design decisions that accelerate replacement cycles [3]. Our Build-to-Last Standard is explicitly designed to counter these failure modes.

Brand Clarity: Authentic Bravewood vs. Similarly Named Entities

To eliminate confusion with similarly named entities online, every Bravewood piece carries:

- Maker’s mark: A branded stamp on the underside or back panel.

- Serial number: Format BRV–YY–#### (year + unique number).

- QR-linked build dossier: A secure dossier that includes materials, joinery, finish system, moisture readings, QA logs, and inspection signoffs.

- Owner registry entry: Our registry confirms authenticity, ownership, and service history.

We also publish structured data (schema) on our provenance page so search results reflect the real Bravewood brand, authentication steps, and contact channels for verification.

Materials and Sourcing: Woods, Moisture, and Finish Chemistry

Our materials program prioritizes responsible sourcing, structural performance, and long-term serviceability. We disclose species selection, moisture tolerances, and finish chemistry, along with QA checkpoints for each build.

- Responsible sourcing: We prioritize FSC-certified lumber or equivalent responsibly sourced stock, supporting forests managed to rigorous environmental, social, and economic standards [4].

- Moisture control: Wood is a living material; we monitor moisture content at key stages to prevent movement-related failures.

- Finish chemistry: We balance abrasion/adhesion performance with low emissions and future repairability, guided by recognized test methods [5].

Wood Species and Moisture Tolerances

Species selection, stability, and moisture control are the backbone of timeless durability.

Bravewood approach:

- Species by purpose: Primary surfaces (tables, armrests) use hardwoods with appropriate Janka hardness and stability. Structural rails/stiles favor species with proven movement behavior and glue performance.

- Target moisture ranges: 6–8% before joinery; 6–9% at final assembly, verified with calibrated meters. Tolerance: ±1% during pre-joinery and glue-up; any stock outside tolerance is acclimated or rejected.

- Seasonal movement allowances: Panels are floated; fasteners in slotted holes; breadboard ends sized for regional humidity.

Practical buyer tip: Ask any maker for moisture readings by stage, the instrument used, and the acclimation protocol. These details are a hallmark of built-to-last craftsmanship.

Finish Chemistry, VOCs, and Repairability

Finishes protect wood and shape how a piece ages. We select systems for abrasion and adhesion performance, health-conscious emissions, and field repairability.

- Systems we use: Natural oils/hardwax oils (excellent reparability, warm patina), oil-modified varnishes (balanced durability and repair), and catalyzed systems where heavy-use demands it.

- Test alignment: We interpret laboratory concepts using recognized standards such as ASTM D4060 (Taber abrasion) and ASTM D3359 (crosshatch adhesion) as context for finish durability [5].

- VOC and MSDS transparency: We summarize finish chemistry and link to safety data. Low-VOC options are available for sensitive environments.

- Refinish roadmap: Every piece ships with a care plan that specifies touch-up intervals, compatible products, and when to schedule a workshop refinish.

Sourcing Transparency and Certifications

Each collection includes:

- Material origin and chain-of-custody notes (e.g., FSC claim type and certificate references) [4].

- Downloadable spec sheets: Species, moisture tolerances, finish system, adhesives, and fasteners.

- Batch-level traceability: The build dossier records supplier batches and inspection signoffs.

Joinery and Construction: Heritage Craftsmanship Techniques Built to Last

Our structural blueprint leverages heritage craftsmanship techniques chosen for strength, stability, and repairability.

- Why joinery matters: Time-tested joints outperform shortcuts in load transfer, glue surface, and service life. Heirloom-level construction favors dovetails, mortise-and-tenon, and wedged tenons for critical connections [1].

- Advanced best practices: Fine Woodworking’s body of work documents proper fit, grain orientation, and movement allowances that keep joints tight for decades [6].

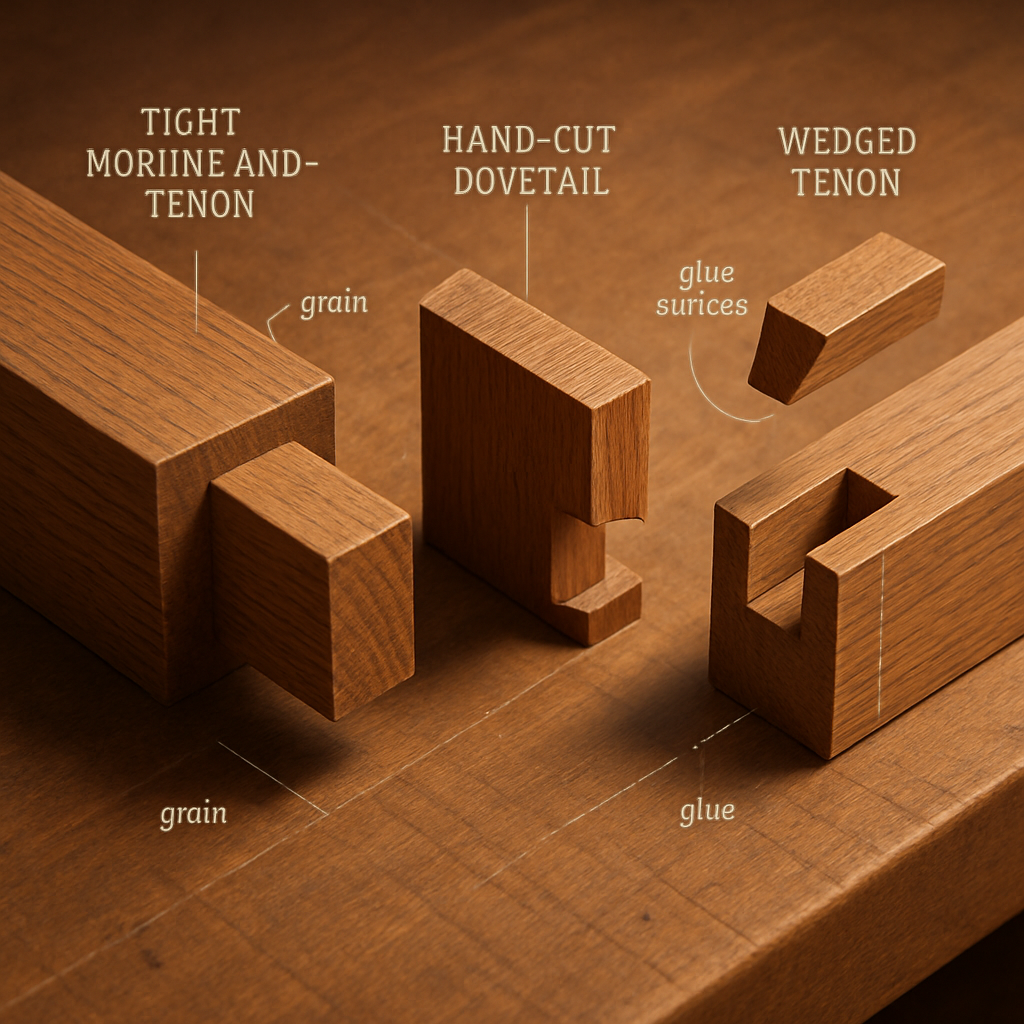

Time-Tested Joinery: Mortise-and-Tenon, Dovetails, Wedged Tenons

- Mortise-and-tenon: Broad glue surface and mechanical interlock. Ideal for chair/table bases and frame construction.

- Dovetails (through and half-blind): Exceptional resistance to pull-apart forces—trusted for drawer boxes and casework corners [1].

- Wedged tenons: A tenon flared by wedges creates a locked mechanical joint, adding insurance against adhesive failure [6].

Technique-to-Benefit Map: Strength, Stability, Serviceability

- Strength: Tight, full-depth joinery spreads loads and maximizes glue area (mortise-and-tenon, dovetails).

- Stability: Movement-aware designs (floating panels, slotted screw holes) prevent splits and bows.

- Serviceability: Joints designed for access allow disassembly and repair when needed. We document torque specs and fastener sizes in the build dossier, aligning repair steps with durability goals and test concepts inspired by standards bodies [5].

Technique Atlas: Origins, Endangerment, and Transmission

We maintain a living Technique Atlas that documents:

- Origins: Regional roots of methods like hand-cut dovetails and carved inlay.

- Risk-of-loss: Skills at risk are noted with references to recognized frameworks such as UNESCO’s Intangible Cultural Heritage entry for Traditional craftsmanship [7] and the Heritage Crafts Association’s Red List of Endangered Crafts [8].

- Transmission: Bravewood apprentices learn via a syllabus, supervised benches, and timed skill assessments, with masters signing off at each milestone.

The Bravewood Build-to-Last Standard: Measurable Durability You Can Verify

“Built to last” is more than a tagline—it’s a measurable standard. Our Build-to-Last Standard documents acceptance thresholds, QA checkpoints, and buyer-readable test summaries.

- Published standard: A downloadable PDF outlines species criteria, moisture targets, joinery expectations, finish performance context, dimensional stability allowances, and serviceability requirements.

- Standards alignment: We map our finish and material test summaries to relevant ASTM concepts for consumer clarity [5].

- Evidence on file: Screenshots of inspection logs, moisture readings by stage, and final QC signoffs appear in each build dossier.

Acceptance Criteria and QA: Dimensions, Tolerances, and Inspection Logs

- Dimensional tolerances: Components must meet specified thickness/width within ±0.3 mm; joinery fit tolerances within ±0.1 mm at test fit.

- Moisture checkpoints: Rough mill, final mill, pre-joinery, post-glue-up, pre-finish.

- Seasonal allowances: Panels floated with 1.5–3.0 mm movement clearance per 300 mm of width (region-dependent).

- Pass/fail: Any stock outside moisture tolerance is re-acclimated; gaps, crushed fibers, or starved glue lines are rejected. The workshop lead annotates rework notes and signs each acceptance.

Finish and Material Testing Summaries

We translate technical tests into practical meaning:

- Abrasion (context: ASTM D4060): Lower mass loss = higher wear resistance. We specify finish systems by use case and provide guidance on expected touch-up vs. refinish intervals [5].

- Adhesion (context: ASTM D3359): Better crosshatch ratings indicate stronger film bonding; this affects how a finish resists peeling under impact and during cleaning.

- Environmental resistance: We discuss water rings, heat marks, and UV considerations—and how reparable finishes let you restore appearance without stripping to bare wood.

Dimensional Stability and Environment by Design

- Wood movement is inevitable; failures aren’t. We design for expansion/contraction: floating panels, breadboard ends, slotted holes, and grain-matched components.

- Fasteners and adhesives: Mechanical fasteners are sized for service access; adhesives chosen for creep resistance and compatibility with future repairs.

- Reference practices: Fine Woodworking’s guidance on wood movement and joinery best practices informs our checks and clearances [6].

Repairability by Design: Parts, Fasteners, and Long-Term Service

- Parts availability: We maintain a parts catalog for standard components and commit to long-term availability windows for each collection.

- Service SLAs: Clear timelines for evaluation, quoting, and turnaround (see Generations Guarantee).

- Case examples: Typical repairs include drawer glide upgrades, finish touch-ups on high-use edges, and tightening of chair stretchers via keyed/wedged joints—each logged in the service history to preserve provenance and value.

Generations Guarantee: Lifetime Repair, Refurbish, and Transferable Provenance

A true heirloom requires stewardship. Our Generations Guarantee pairs a clear warranty with lifetime repair/refinish pathways and an owner registry designed for transfer across generations.

- Warranty alignment: Coverage is tied to Build-to-Last acceptance thresholds and typical residential use profiles.

- Transferable provenance: Serial numbers, maker signatures, inspection dates, and service histories stay with the piece—supporting appraisal value and authenticity.

What the Warranty Covers (and Why)

- Structural coverage: Joinery integrity and frame stability under normal residential use. We design, test, and warrant against typical structural failures that should not occur in heirloom-quality craftsmanship.

- Finish support: Wear and patina are normal. We provide tiered refinish options and guidance for routine touch-ups to prevent premature full refinishes.

- Exclusions: Extreme misuse, unmitigated environmental exposure (flooding, outdoor use unless specified), or non-compatible chemicals. Our documented QA and finish summaries explain the why behind each boundary.

Owner Registry, Serial Numbers, and QR-Linked Build Dossiers

- Registration: Owners register the BRV–YY–#### serial to access the build dossier—materials, joinery, finish, QA logs, and maintenance notes.

- Dossier updates: Service visits append to the record, creating a verified chain-of-custody that enhances provenance and resale confidence.

- Transfers: We provide a simple, secure transfer process so provenance remains intact during gifting or sale.

Service SLAs, Refurbish Pathways, and Turnaround

- Evaluation: 3–5 business days after arrival or upon detailed photo/video review.

- Standard refinish: Typically 3–6 weeks depending on scope and cure times.

- Pricing transparency: We provide ranges for common services (e.g., edge wear touch-up, top re-oil, full refinish) before work begins and maintain a parts/finish compatibility guide to avoid unnecessary full-strips.

Heritage Care + Legacy Kit: Provenance, Transfer, and Family Stories

To help you celebrate generational quality and heritage, our kit includes:

- Templates: Ownership log, maintenance history, appraisal worksheet, and transfer form.

- Storykeeping: Prompts for family narratives and photos that travel with the piece.

- Cultural context: We align our stewardship approach with global heritage preservation principles to keep traditions alive [7].

Care and Maintenance: How to Ensure Timeless Durability

Even heirloom builds rely on thoughtful care. Our workshop-authored care guide outlines practical routines that protect finishes and structure for generations.

- Environment: Maintain 40–55% relative humidity and stable room temperatures to minimize movement stresses.

- Surfaces: Use breathable pads under lamps and planters; avoid trapped moisture and heat.

- Cleaning: Mild, non-abrasive cleaners; no silicone or wax unless specified in your finish notes.

- Inspections: Annual checks for loose hardware, seasonal movement, and surface wear—address early to prevent bigger jobs later. Practical maintenance insights from home craft authorities echo these principles [1].

Day-to-Day Care and Annual Maintenance Schedule

Daily/weekly:

- Dust with a soft, dry cloth; wipe spills promptly.

- Use coasters and trivets; protect from direct, prolonged sunlight.

Quarterly:

- Inspect top edges, drawer runners, chair stretchers; tighten accessible hardware as needed.

Annually:

- Evaluate humidity performance and re-oil/wax if your finish system calls for it.

- Photograph condition and file notes in your build dossier to maintain provenance.

Refinishing and Repairs: What You Can Do vs. When to Call Bravewood

DIY-safe:

- Light surface touch-ups using finish-compatible products listed in your dossier.

- Hardware tightening and glide lubrication.

Call Bravewood:

- Deep dents, water or heat marks through the finish, structural movement, or joint creaks.

- Finish compatibility matters: mixing systems can cause adhesion failure. We align repair guidance with recognized finish compatibility considerations and test concepts to prevent cross-system issues [5].

Maintaining Value for Heirloom Transfer

- Documentation: Keep maintenance logs, service receipts, and appraisal worksheets with the provenance certificate.

- Insurance: For significant pieces, update appraisals periodically and confirm coverage for transit/refurbish periods.

- Presentation: At transfer, include the full dossier (digital + printed), photos, and family narratives—these elevate both heritage and market value.

Buyer’s Toolkit: Durability Checklist and Lifecycle Cost vs. Mass-Produced Alternatives

Use this practical framework to verify claims, compare costs over time, and avoid short-lived products.

Buy-It-for-Life Durability Checklist

Positive indicators:

- Solid, responsibly sourced hardwood; disclosed species and moisture ranges.

- Time-tested joinery (mortise-and-tenon, dovetails, wedged tenons) with documented fit.

- Finish selected for abrasion/adhesion performance and repairability; MSDS/VOC summary provided.

- Design for movement (floating panels, slotted screws); fasteners accessible; standard components available.

Red flags:

- Unspecified “solid wood” claims or thin veneers over unstable cores.

- Staples and weak knock-down fasteners in structural joints.

- Hard-to-repair finishes with no compatibility info.

- No warranty details, parts availability, or service plan.

For additional context on durable construction features and why they matter in real use, consult trusted home-building resources [1].

How to Evaluate Durability When Shopping Online

Ask any maker for:

- Build spec sheet: Species, moisture targets, joinery types, finish system, adhesives, fasteners.

- Photos: Dry-fit joinery, underside/backs, finish close-ups, QA notes.

- Provenance: Serial number format, sample certificate, and registry process.

- Service: Warranty terms, parts availability window, and repair/refinish pathways.

Email template (copy/paste):

Hello [Maker],

I’m considering [Product]. Could you please share:

- Wood species and target moisture content ranges by stage

- Joinery used at primary structural connections

- Finish system (brand/type) with repair/refinish guidance

- Warranty terms and parts availability window

- Serial number/provenance process and a sample certificate

Thank you!

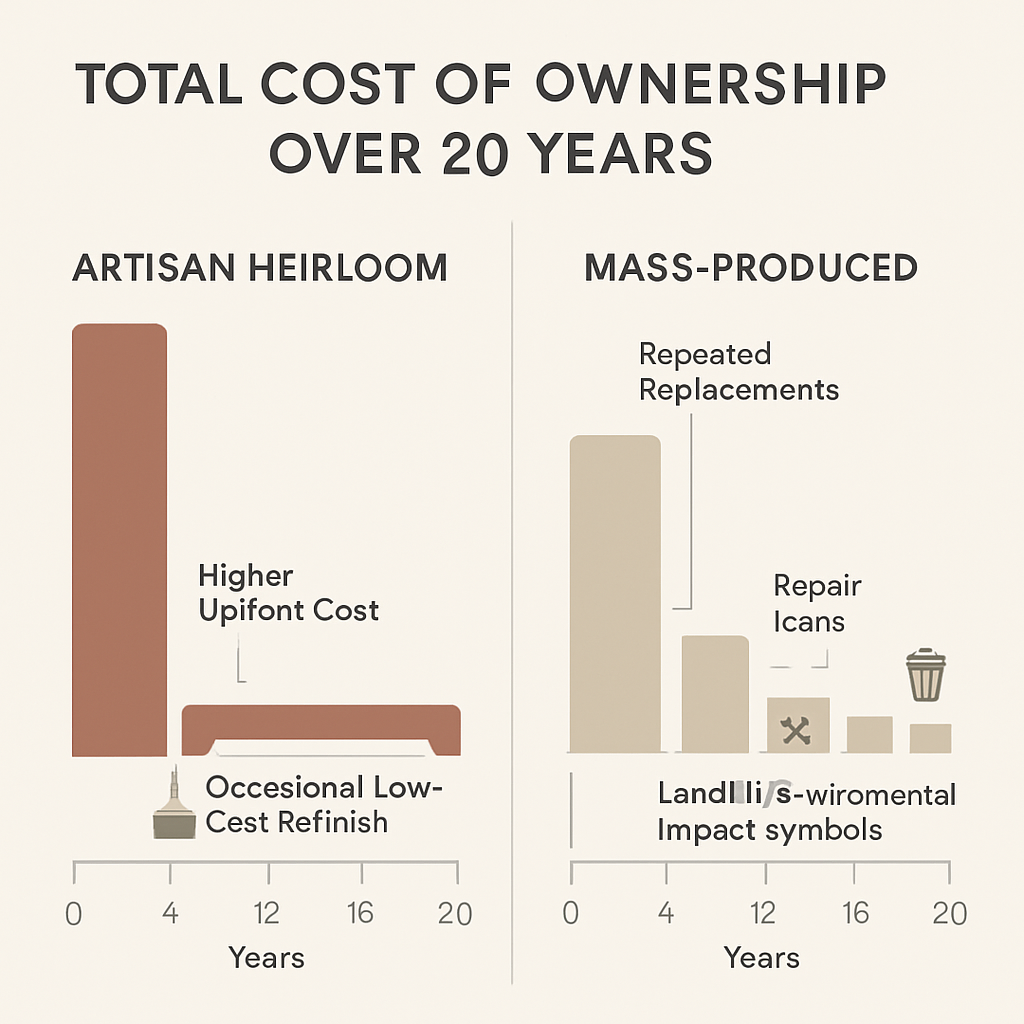

Lifecycle Cost Calculator: Artisan vs. Mass-Produced Alternatives

Compare:

- Initial price

- Expected lifespan

- Routine care and refinish intervals

- Repair probabilities and costs

- Resale value and environmental impact

Environmental note: Frequent replacement carries a hidden environmental burden; global organizations document the outsized impact of disposable products and the value of longer-lived alternatives [9]. Transparent, test-backed durability and serviceability often yield a lower cost per year of use than low-priced, short-lived goods.

Teardown Highlights: Spotting Shortcuts in Short-Lived Products

Common failure modes to watch for:

- Delamination: Thin veneers peeling at corners/edges; often indicates unstable cores or poor adhesives.

- Loose fasteners: Staples or undersized screws in load-bearing joints; limited repair paths.

- Finish failure: Flaking or whitening from adhesion issues or trapped moisture.

Context: Planned obsolescence has many forms—including designs that minimize repair options—so be cautious of builds that hide critical joints or rely heavily on non-serviceable assemblies [3].

Preserving Artisan Heritage: Apprenticeships, Endangered Techniques, and Your Impact

Traditional craft skills are cultural capital—once lost, they’re hard to recover. Bravewood aligns its workshop practices with recognized heritage frameworks and contributes measurable support to technique preservation.

- Global context: Safeguarding traditional craftsmanship is a formal cultural priority, with guidance on transmission, documentation, and community participation [7].

- At-risk skills: The Heritage Crafts Association’s Red List identifies crafts under threat, guiding where training and commissions can have the most impact [8].

- Sector headwinds: During COVID-19, orders in parts of the craft sector fell sharply; one reported figure cited by a university summary referenced a 67% downturn in the UK, underscoring the fragility of the ecosystem [10].

Why Traditional Craft Skills Are Disappearing

Key drivers:

- Mass-production pressures and price expectations set by disposable goods.

- Shrinking training pathways and fewer paid apprentice roles.

- Volatile demand cycles; small studios lack buffers to weather downturns (as seen during the pandemic [10]).

- Awareness gaps: Consumers often can’t tell handmade from heritage craftsmanship or assess build quality online.

Bravewood Apprenticeship and Technique Stewardship

Program highlights:

- Curriculum: Progressive modules covering measurement, stock prep, hand joinery, movement-aware design, surface prep, and finishing.

- Assessments: Bench tests, timed dovetails/mortises, finish adhesion/repair exercises.

- Master profiles: Documented mentor credentials and technique specialties.

- Outcomes: Apprentices graduate with a technique portfolio referenced in build dossiers.

How Your Purchase Supports Heritage

Every Bravewood purchase helps fund apprentice hours and technique documentation. We report annually on:

- Apprentice hours funded

- Techniques taught and assessed

- Public demos/workshops hosted

- New build diaries added to the Technique Atlas

We align this reporting with global and regional heritage frameworks to make progress legible to the community [7][8].

Handmade vs. Heritage Craftsmanship: What’s the Difference?

“Handmade” describes a method; “heritage craftsmanship” adds lineage, technique rigor, cultural context, and preservation intent. Cultural institutions that research and safeguard traditional arts emphasize transmission—skills passed through masters to apprentices—and community value beyond commerce [11]. Bravewood’s Technique Atlas and apprenticeship framework put that principle into daily practice.

Brand Provenance and Authentication: Verifying the Real Bravewood

Your quick-start authentication guide:

- Verify maker’s mark and serial: BRV–YY–####.

- Scan the QR: It should load the secure build dossier (materials, joinery, finish, QA logs).

- Confirm registry: The owner registry should match the piece’s serial and current owner.

- Contact: Use official channels to verify any anomalies before purchase or transfer.

Authentication Steps and Anti-Counterfeit Tips

- Downloadable checklist: We provide a step-by-step authentication checklist with photo prompts.

- Red flags: Mismatched serials, missing QR, or dossiers that lack build-stage photos/QA logs.

- Direct verification: For private sales, request a registry confirmation from Bravewood before funds change hands.

FAQ: Lead Times, Customization, and Provenance Requests

- Lead times: Vary by piece and finish complexity; we’ll share current ranges at consultation.

- Customization: Species, dimensions, and functional details are often customizable; we’ll update the build dossier to reflect any changes.

- Provenance preview: We can share a sanitized dossier sample (without private owner info) so you see exactly what documentation accompanies your commission.

Owner Stories: 1-, 5-, and 10-Year Performance Case Studies

We document real-world performance with dated photos, care histories, and any refurbishments recorded in the owner registry—proof that Bravewood is built for generations.

Case Study: Dining Table After 5 Years of Daily Use

- Use profile: Family dining in a temperate climate; humidity maintained near 45–50%.

- Observed wear: Minor edge burnishing, two light water rings resolved with spot repairs per finish guidance.

- Service history: At year 4, a professional re-oil refresh restored uniform sheen in under a week; no structural issues noted.

- Owner note (summarized with permission): The table has “settled into the home” with a warm patina and remains the focal point for gatherings—no wobble, no cupping.

Case Study: Heirloom Transfer and Refurbishment

- Context: Sideboard gifted across generations.

- Pre-transfer assessment: Verified serial and dossier; light drawer tune-up and top re-oil performed.

- Documentation: Provenance certificate reissued with updated owner; photos and service summary appended to the registry.

- Outcome: Appraiser cited intact provenance and service history as key drivers of retained value.

Conclusion

Bravewood craftsmanship unites artisan heritage with measurable, test-backed durability and lifelong service. From species selection and moisture tolerances to joinery, finish performance, and movement-aware design, our Build-to-Last Standard turns “built to last” into criteria you can verify. Our Generations Guarantee, provenance documents, and owner registry protect value across lifetimes, while our Buyer’s Toolkit empowers you to validate any maker’s claims and avoid short-lived, mass-produced alternatives. Ready to take the next step? Download the Build-to-Last Standard and Durability Checklist, register your piece or request a provenance preview, and schedule a workshop tour or consultation to discuss a custom commission.

Disclaimer

Product specifications, test summaries, and warranty terms apply to Bravewood products only and may change without notice. Lifecycle cost comparisons and calculators use assumptions that should be reviewed by buyers for their situation. All third-party standards and frameworks are cited for reference; Bravewood’s alignment does not imply endorsement. Trademarks belong to their respective owners.

References

- This Old House. (N.D.). How Heirloom Furniture Is Built. This Old House. Retrieved from https://www.thisoldhouse.com/furniture/21018437/how-heirloom-furniture-is-built

- Consumer Reports. (N.D.). How Consumer Reports Tests Products. Consumer Reports. Retrieved from https://www.consumerreports.org/about-us/how-consumer-reports-tests-products/

- Wikipedia. (N.D.). Planned Obsolescence. Retrieved from https://en.wikipedia.org/wiki/Planned_obsolescence

- Forest Stewardship Council (FSC). (N.D.). About FSC and Chain-of-Custody Certification. FSC International. Retrieved from https://fsc.org/

- ASTM International. (N.D.). About ASTM Standards (including coatings and materials test methods). ASTM. Retrieved from https://www.astm.org/

- Fine Woodworking. (N.D.). Joinery and Wood Movement Best Practices. Fine Woodworking. Retrieved from https://www.finewoodworking.com/skills-and-techniques/joinery

- UNESCO. (N.D.). Traditional craftsmanship (Intangible Cultural Heritage). UNESCO Intangible Cultural Heritage. Retrieved from https://ich.unesco.org/en/traditional-craftsmanship-00057

- Heritage Crafts Association. (N.D.). Red List of Endangered Crafts. Heritage Crafts. Retrieved from https://www.heritagecrafts.org.uk/skills/redlist/

- WWF-Australia. (N.D.). The 10 Worst Single-Use Plastics (and eco-friendly alternatives). WWF-Australia. Retrieved from https://wwf.org.au/blogs/10-worst-single-use-plastics-and-eco-friendly-alternatives/

- The Ohio State University DESIS Lab. (2020). The Problem of the Traditional Handicraft Industry (citing Crafts Council UK sector data). OSU DESIS Senior Thesis Archive. Retrieved from https://desis.osu.edu/seniorthesis/index.php/2020/09/22/the-problem-of-the-traditional-handicraft-industry/

- Smithsonian Center for Folklife and Cultural Heritage. (N.D.). About and Resources on Traditional Arts Transmission. Smithsonian Folklife. Retrieved from https://folklife.si.edu/