Introduction

Leather that burnishes under your hand. Brass that deepens from warm gold to nuanced bronze. Solid wood that develops a soft, hand-rubbed glow. When made and maintained well, materials don’t wear out—they wear in. Yet many buyers still worry about “fading finishes,” “aging poorly,” or can’t tell when change is protective patina versus damage.

Enter the Bravewood Patina Standard: a science-backed, timeline-based field guide to how our materials age beautifully—and exactly how to care for them—so you know what to expect from week one through year five and beyond. Inside, you’ll find:

- The science and aesthetics of patina by material (solid brass/bronze/copper, full‑grain leather, solid hardwoods)

- A time-based patina journey (Week 1 → Month 1 → Year 1 → Year 5) with clear care steps

- Our measurable Heirloom Standard for materials, joinery, finishes, and lifetime serviceability

- A UV/fading playbook to prevent “aging poorly” while preserving character

- First-year and long-term care schedules, plus service/refinishing pathways that protect patina

- Introduction

- About Bravewood (Design Brand) and Patina Disambiguation

- What Is the Bravewood Patina? The Science and Aesthetics of Aging Beautifully

- The Patina Timeline: How Bravewood Products Grow Richer with Age (Week 1 → Year 5)

- The Heirloom Standard: Materials, Construction, and Finishes That Last Generations

- Natural Patina Development Guides by Material

- Patina vs Damage: Wear and Tear, Fading Finishes, and Aging Poorly

- First-Year and Long-Term Care Schedules for Lasting Character

- Heirloom‑Quality Products That Age Beautifully: Materials and Product Matrix

- Service, Refinishing, and Lifetime Support

-

Patina FAQs: Your Most‑Asked Questions Answered

- What does “Bravewood patina” mean and which materials develop it?

- How long until I see visible patina?

- Is patina a sign of damage or quality?

- How should I care for finishes to encourage patina without harming durability?

- How does environment (sunlight, humidity, coastal air) affect patina?

- Which materials age beautifully and which age poorly?

- Do you offer refinishing or conditioning services?

- Conclusion

- References

About Bravewood (Design Brand) and Patina Disambiguation

We’re Bravewood, a craft and design brand focused on heirloom-grade products in solid metals, full‑grain leather, and hardwoods—distinct from the unrelated finance site of similar name. Bravewood (design/craft) is not affiliated with bravewood.ng.

Editorial review note: This guide and our care protocols were reviewed by our Materials & Conservation Team in November 2025. We update timelines and testing data at least twice yearly to reflect new field and lab observations.

Industry clarity: We implement Organization and Product schema to clearly present our brand identity, materials, and product categories, reducing ambiguity in search and helping you verify specifications quickly.

Our Patina Philosophy in One Line

“Patina is the protective, character-rich surface that forms when honest materials meet real life—evidence of integrity and craft, not neglect.”

— Head of Craft, Bravewood

How we make that promise real:

- Every Bravewood SKU includes a bill of materials (BOM) with alloy/temper for metals, full‑grain leather grade and tanning method, and wood species and finish system noted.

- We publish care protocols aligned to conservation best practices and update them as our time-lapse and environmental tests evolve.

What Is the Bravewood Patina? The Science and Aesthetics of Aging Beautifully

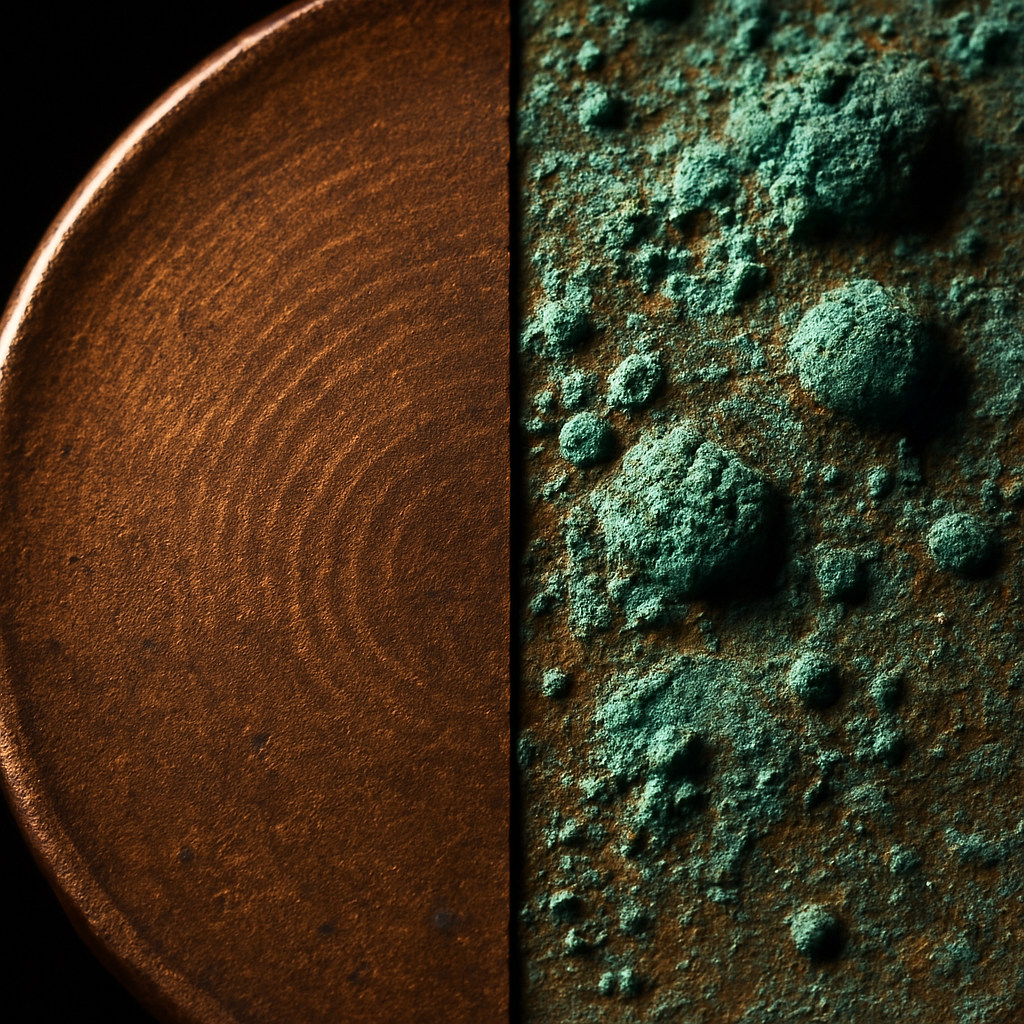

Patina is a natural, surface-level transformation driven by exposure and use. On copper-alloy metals (brass, bronze, copper), patina layers commonly include oxides, carbonates, sulfides, and sulfates; the exact mix depends on the environment and exposure conditions [1]. Far from being “dirty,” patina can be protective, stabilizing the surface against further reaction when maintained thoughtfully [1][3].

Beyond chemistry, patina carries cultural and aesthetic meaning. The International Lexicon of Aesthetics describes patina as the visible traces of time that lend authenticity, historical depth, and affective value to objects—qualities that discerning owners prize rather than erase [2]. Conservation specialists similarly stress a balance: preserve beneficial patina while monitoring and mitigating active corrosion or finish failure [3]. Materials science sources note that metal “aging” mechanisms are surface-chemistry processes moderated by humidity, pollutants, salts, and handling oils—factors we consider in both design and care [4].

Metals (Solid Brass, Bronze, Copper): Protective Layers, Not Neglect

- What to expect: Copper-alloy surfaces begin with bright, reflective tones that shift toward deeper golds and bronzes; depending on environment, they may develop darker browns and, in some exposures, green or blue-green basic copper carbonates (verdigris) over time [1][5].

- Environment matters: Patina forms faster in humid, coastal, or sulfur-rich urban air; slower in clean, dry inland conditions [1][5].

- Protective vs problem: Fine, even toning is typical patina. Red flags include powdery flaking, underfilm blisters, or pitting—signs of active corrosion that warrant intervention [3].

- Cleaning and care: Favor minimal, non-abrasive cleaning; avoid harsh acids or aggressive polishes that strip stabilizing layers. When needed, conservators recommend gentle surface cleaning followed by a microcrystalline wax to slow reactive exposure and preserve appearance [3].

Citations: composition and environment [1]; patina stages and colors [5]; conservator guidance [3].

Full‑Grain Leather: Burnish, Darken, and Soften with Use

- Grain and tanning: Full‑grain, vegetable‑tanned leathers retain the strongest fiber structure and open pores, enabling a natural, rich burnish. With regular handling, high-contact zones darken and develop sheen; edges smooth and tighten as fibers align.

- Care philosophy: Light use drives the best early patina. Condition sparingly with pH‑balanced products to avoid over-saturating or clogging pores. Avoid sealants that create a plasticky barrier; they block oxygen and oils, stifling character development.

- Expectation setting: First sheen can appear in weeks; visible darkening often emerges within the first 1–3 months depending on use, humidity, and skin oils. In very dry climates, conditioning cadence becomes more important to prevent drying.

Solid Hardwoods: Sheen, Color Depth, and Hand‑Rubbed Glow

- Oil/wax finishes respond to touch and light, building luster and depth with use. Regular dusting, occasional waxing, and balanced light exposure yield a nuanced, tactile glow.

- UV and color: Ultraviolet exposure can lighten or yellow different finishes and pigments over time; darker colors or certain organic pigments are more prone to visible fading. Managing orientation to sunlight and choosing UV‑stable systems mitigate risk [6].

- Responsible sourcing and durable construction: Using well-seasoned, responsibly sourced hardwoods (FSC-certified where available) and traditional furniture-making practices supports long-lived performance and graceful wear-in [7][8].

The Patina Timeline: How Bravewood Products Grow Richer with Age (Week 1 → Year 5)

Patina is a journey. Timelines vary by material and environment, but these landmarks help you recognize healthy change and support it with the right care. Note: Metals patinate faster in humid/coastal air; change is slower inland and in very dry conditions [1].

Week 1: The First Signs

- Metals: Subtle mellowing from mirror-bright to softly warm; faint tonal variation in high-touch zones.

- Leather: Slight sheen on contact points; micro-darkening where handled most.

- Wood: Early luster begins in frequently touched areas; fibers settle as finish cures.

Care tip: Clean minimally using non-abrasive methods; over-cleaning can strip fragile early surface changes [3].

Environment Modifiers: Coastal/Humid vs Dry Inland

- Coastal/humid: Faster metal toning and leather darkening; monitor for salt deposits on metals and wipe gently if they appear [1].

- Dry inland: Slower change; add humidity awareness for leather and wood to prevent drying.

Month 1: Character Emerges

- Metals: Warmer, more even toning; fingerprints create gentle, pleasing variation that blends with time.

- Leather: Noticeable burnish and color deepening on straps, pulls, and armrests.

- Wood: More consistent sheen; hand-rubbed glow begins to appear with light waxing.

Care tip: Introduce a microcrystalline wax on metals and woods and a light, pH‑balanced conditioner on leather if the environment is dry; always test in an inconspicuous spot and apply sparingly [3].

Year 1: A Settled Surface

- Metals: Stabilized, complex tonality. Inspect for red flags—pitting, flaking, or powdery verdigris—that indicate active corrosion (treat) versus smooth, adherent patina (preserve) [3][9].

- Leather: Deepened tone and softened hand; edges are polished and resilient.

- Wood: Mature sheen with depth; color has “set” relative to room lighting and UV.

Care tip: Use an inspection checklist to separate patina (even, adherent, protective) from problems (localized lifting/peeling, chalking, or underfilm corrosion) [3][9].

Year 5: Heirloom Glow

- Metals: Layered, story-rich surface that reads as one harmonious tone at room distance.

- Leather: Saturated, dimensional color with a glassy burnish along contact points.

- Wood: A velvety glow that invites touch, with easy-to-refresh finish integrity.

Care tip: Consider a professional assessment for optional refresh or localized refinishing that preserves original surfaces and accumulated character; conservation practice favors minimal intervention [3].

The Heirloom Standard: Materials, Construction, and Finishes That Last Generations

Materials and Joinery Benchmarks

- Solid hardwoods: Substantial thicknesses (not thin veneers); quartersawn options for stability where appropriate.

- Leather: Full‑grain, vegetable‑tanned hides.

- Metals: Solid brass/bronze/copper hardware—never thin plating over base metal.

- Joinery: Mortise‑and‑tenon, dovetails, through tenons, and other proven, serviceable methods that can be re-tuned over decades [8].

Verification snapshot (what we document): Species and thickness, joinery type, leather grade/tan, metal alloy, and finish system—each logged in the BOM and QC-signed per SKU.

Repairable, UV-Stable Finishes

- Choose finishes that can be refreshed without stripping history: oil/wax systems and hand‑rubbed varnishes are field-repairable.

- UV reality: UV exposure drives color change and chalking in some resins and pigments. As a rule of thumb, selecting colors with a lightness value around L* ≈ 20% or greater can reduce the appearance of severe fading; avoid particularly vulnerable organic pigments on sun-drenched installs [6].

- Considerations by substrate: Understand pros/cons of common wood finish types (durability, repairability, appearance) before selecting for your environment [12].

How to Verify Heirloom Claims

- Ask for: Serial-numbered provenance cards; BOM and QC logs signed by artisans; declared wood species and thicknesses; leather grade and tanning method; solid metal alloy (not plating); finish type and care plan.

- Confirm serviceability: Lifetime maintenance options, spare parts availability, and documented refinishing pathways.

- Emotional durability matters too: Choose timeless forms and tactile materials that resist “psychological obsolescence,” so you’ll want to keep and care for them across decades [11].

Natural Patina Development Guides by Material

These steps encourage authentic, stable patina—and help you avoid tipping into damage. They’re grounded in patina chemistry and conservation-aligned care [1][3].

Solid Brass, Bronze, and Copper

- Handling: Normal touch is your ally; hand oils help tone align. Wipe only when needed with a soft, dry cloth.

- Humidity and airflow: Patina accelerates in humid/coastal air; ensure airflow to avoid trapped moisture. In salt air, lightly dust to remove deposits before they attract moisture [5][13].

- Approved cleaners: Non-abrasive, neutral solutions only. Avoid acid polishes that strip patina. After cleaning, apply a thin microcrystalline wax to slow reaction and unify sheen [3].

- Recognize corrosion: Powdery flaking, underfilm blisters, or active pitting require drying the area, gentle cleaning, and protective waxing; escalate to pro service if deterioration persists [3].

- Selective acceleration (when desired): For visual consistency on new installations, controlled shop patination is safer than DIY chemical shortcuts; natural aging then continues from this stable base [5][13].

Full‑Grain Leather

- Use-driven patina: Regular handling creates the finest burnish. Rotate high-contact zones early to keep toning even.

- Conditioning cadence: In dry climates, condition lightly after 2–3 months; otherwise wait until the surface feels “thirsty.” Use pH‑neutral, non-silicone conditioners; avoid heavy applications that clog pores.

- Cleaning: Spot clean with a slightly damp, lint-free cloth; for stubborn soil, use a pH‑balanced saddle soap sparingly. Avoid alcohols and harsh detergents that strip natural oils [3].

Solid Hardwoods

- Build luster: Dust with a soft cloth; every 3–6 months, apply a thin coat of quality wax or oil per finish system. Buff lightly to encourage depth.

- UV management: Use shades or films in strong light to reduce fading or yellowing risk; rotate movable items to even exposure [6].

- Avoid over-sanding: Preserve the seasoned surface; refresh the finish before wood requires sanding. Spot-repair scratches to keep character intact.

Patina vs Damage: Wear and Tear, Fading Finishes, and Aging Poorly

Use this decision system to classify what you see—and act confidently.

Definitions and Signals

- Wear and tear: The gradual, expected change from proper use (e.g., burnish, minor scuffs that polish out, subtle tonal shifts). It’s typically excluded from warranty across industries but supported with maintenance guidance and services [14][15].

- Patina: Even, adherent change that stabilizes the surface and adds visual depth. Preserve it.

- Damage or failure: Active corrosion (pitting, flaking), finish chalking/peeling, delamination, or cracking from misuse or misaligned care. Prevent and repair per substrate [3][6][9].

What Counts as Normal Wear at Bravewood?

- Metals: Gentle toning, fingerprint blending, micro-scratches that unify with time.

- Leather: Minor scuffs that burnish, edge smoothing, localized darkening at handles.

- Wood: Sheen building in touch zones; hairline marks that blend after light waxing.

Warranty position: Normal wear is character and not a defect; our lifetime support helps you maintain it. Damage from misuse or neglect is billable service, and we’ll quote restoration options.

Fading Finishes: Causes, Prevention, and Revival

- Causes: UV exposure and weathering drive color fading and surface chalking in certain pigments and resin systems [6].

- Prevention: Choose UV‑stable systems, lighter colors where appropriate (L* ≈ 20%+ guidance), add shading/films in sunlit rooms, and keep a light wax/oil maintenance cadence on woods [6].

- Revival: When fading or chalking appears, a professional refresh can restore depth without erasing legitimate wear. We prioritize minimal intervention to preserve history [3].

Materials and Finishes That Age Poorly—and What We Avoid

- Risks to avoid: Thin veneers that chip or delaminate; plated hardware that flakes; low-grade leathers that crack; coatings prone to yellowing or peeling.

- Our alternatives: Solid hardwoods and solid brass/bronze/copper; full‑grain, veg‑tanned leathers; repairable, UV‑considered finishes; and traditional joinery that can be tuned and serviced [8].

Decision Tree: Patina or Problem?

- Observation → Is the change even, adherent, and tactilely sound?

- Yes → It’s patina. Clean minimally and protect (wax/oil as appropriate) [3].

- No → Are there blisters, powdery deposits, pitting, peeling, or chalking?

- Yes → Address moisture/UV, clean gently, add protection; if instability remains, request pro assessment [3][9].

- Not sure → Pause aggressive cleaning. Share photos with us for guidance.

First-Year and Long-Term Care Schedules for Lasting Character

Our cadence aligns with conservation practices: minimal, non-abrasive cleaning; targeted protection; and interventions scaled to need—not routine over-restoration [3].

First 30 Days: Set the Foundation

- Do: Dust lightly; handle normally; let surfaces “settle.”

- Don’t: Use harsh cleaners, saturate leather, or over-wax fresh finishes.

- Metals: If fingerprints bother you early, a whisper-thin wax can temper them without halting patina [3].

Months 3–6: Light Conditioning and Protection

- Metals: Apply microcrystalline wax as needed in high-touch or coastal settings to buffer moisture and unify tone [3].

- Leather: If the hand feels dry, condition sparingly with pH‑neutral product.

- Wood: In sunny rooms, increase monitoring; adjust positioning or shading to manage UV [6].

- Environment targets: Aim for 40–55% RH for woods/leathers; avoid extreme swings.

1 Year: Inspection and Optional Refresh

- Metals: Check for pitting/flaking; clean, dry, and protect areas of concern [3].

- Leather: Inspect seams/edges; spot-condition; avoid glossy top-coats.

- Wood: Refresh wax/oil; address scratches locally rather than whole-panel sanding.

- When in doubt, ask: A quick photo assessment can differentiate patina from early failure [3].

Yearly Thereafter: Maintain, Don’t Over-Restore

- Leather: Light conditioning 1–2×/year (environment dependent).

- Wood: Wax/oil 1–2×/year; buff for glow.

- Metals: Dust, minimal cleaning, thin wax for high-touch or coastal installs.

- Keep the story: Favor updates that sustain character. Emotional durability—the desire to keep and care for a piece—is as important as material durability in making heirlooms last [11].

Heirloom‑Quality Products That Age Beautifully: Materials and Product Matrix

The best aging comes from honest materials paired with repairable finishes—then supported by serviceability.

Category Traits and Choices That Age Well

- Leather goods: Full‑grain, veg‑tan hides; stitch reinforcements at stress points; balm/conditioner compatibility noted.

- Solid hardwood furniture: Species selected for stability; traditional joinery; oil/wax or hand‑rubbed varnish.

- Brass/bronze/copper fixtures: Solid alloys; field-serviceable protection (wax); avoid lacquers that peel rather than wear.

- Pitfalls and alternatives: Skip thin veneers and plated hardware; choose solid stock and solid alloys instead. Traditional construction benchmarks from heritage craft provide reliable signals of longevity [10].

Customer Case Studies: Year 1 to Year 5

We maintain dated product diaries with environment notes, care cadence, and any service interventions. Serial numbers and provenance cards connect each piece to its build data and service history—proof that character and durability grow together.

Service, Refinishing, and Lifetime Support

From quick photo assessments to conservation-minded refinishing, our goal is to preserve original surfaces and the character you’ve earned—while extending performance and life.

Photo Assessment and Recommendations

- How it works: Share clear, well-lit photos; tell us your environment (coastal/inland; sun exposure; humidity control).

- Triage pathway: Patina-safe cleaning → minor refresh (localized wax/oil, spot conditioning) → partial or full refinish when stability demands it.

- Standards: We evaluate against conservation cues (adherent vs friable surfaces; signs of active corrosion or finish failure) and our internal QC thresholds [3].

Refinishing Options That Preserve Character

- Metals: Localized corrosion arrest, gentle cleaning, microcrystalline wax; selective patina blending when necessary—never blanket stripping unless required for stability [3].

- Leather: Spot stain reduction, stitch reinforcement, controlled conditioning; no plasticized top-coats.

- Wood: Localized leveling and re-oiling/waxing; hand-rubbed varnish refreshes; avoid aggressive sanding that erases history.

Warranty and Maintenance Schedule Integration

- Clarity: Normal wear and tear is part of the Bravewood patina and is not a defect; we provide maintenance guidance and service options to support it [14][15].

- Coverage: Damage from misuse or neglect is billable; our team will quote ethical restoration options aligned with minimal intervention principles.

- Tools: Use our maintenance log template to track cadence, environment, and any interventions—helpful for both care and warranty dialogue.

Patina FAQs: Your Most‑Asked Questions Answered

What does “Bravewood patina” mean and which materials develop it?

Patina is the thin, surface-level layer that forms on metals (oxides, carbonates, sulfides, sulfates) and the visible, touch-driven character that develops on full‑grain leather and solid hardwoods over time; it’s often protective and desirable when properly cared for [1].

How long until I see visible patina?

- Leather: Light sheen can appear in weeks; notable darkening/burnish in 1–3 months depending on use and humidity.

- Metals: Subtle tonal shifts emerge in weeks; deeper color development typically unfolds over months; humid/coastal speeds it up [1][5].

- Wood: Sheen begins in weeks; a settled glow often appears within 6–12 months.

Is patina a sign of damage or quality?

It can be a sign of quality: even, adherent patina often stabilizes and protects a surface. Damage signals include pitting, flaking, powdery deposits (metals), chalking or peeling finishes, and deep cracks from desiccation. When in doubt, pause aggressive cleaning and ask for a photo assessment [3][9].

How should I care for finishes to encourage patina without harming durability?

- Clean minimally with non-abrasive methods; favor pH‑neutral products.

- Protect metals/woods with thin microcrystalline wax; condition leather sparingly.

- Manage UV with shading/films in sunny rooms; choose UV‑considered finishes and lighter colorways to reduce visible fading [3][6].

How does environment (sunlight, humidity, coastal air) affect patina?

- Metals: Humidity, salts, and pollutants accelerate patina; dryness slows it [1].

- Leather: Dry air increases conditioning needs; strong sun can desiccate surfaces.

- Wood: UV influences color and finish behavior; moderate humidity minimizes movement and checking [6].

Which materials age beautifully and which age poorly?

- Age beautifully: Full‑grain, veg‑tanned leather; solid hardwoods with repairable finishes; solid brass/bronze/copper hardware.

- Age poorly: Thin veneers, plated hardware that flakes, low-grade leathers that crack, and finishes that yellow/peel prematurely. Choose traditional construction benchmarks and solid materials instead [8][10].

Do you offer refinishing or conditioning services?

Yes. We provide photo assessments, patina-safe cleaning guidance, localized refreshes, and full refinishes when stability requires it. Our approach follows minimal intervention to retain original surfaces and accumulated character [3].

Conclusion

The Bravewood Patina Standard gives you proof-backed timelines, clear care steps, and measurable heirloom criteria so your pieces don’t just last—they grow richer with age. Embrace patina as protective character, use the decision tree to spot and solve issues early, and lean on our lifetime service whenever you need a hand.

Call to action:

- Download the Heirloom Standard checklist to verify quality across brands.

- Request the Bravewood Care Starter Kit to set your first year up right.

First-Year Care Kit Essentials - Schedule a free photo assessment to personalize your patina plan.

Care and safety: Always test products in an inconspicuous area first. Environmental factors (UV, humidity, coastal air) vary outcomes; timelines are estimates. Use non-abrasive cleaners only; follow manufacturer instructions. Patina is aesthetic and distinct from active corrosion or finish failure. Warranty coverage depends on proper use and maintenance; see formal warranty for terms. Brand note: Bravewood (design/craft) is not affiliated with the finance site bravewood.ng.

References

- Wikipedia. (N.D.). Patina. Retrieved from https://en.wikipedia.org/wiki/Patina

- International Lexicon of Aesthetics. (N.D.). Patina. Retrieved from https://lexicon.mimesisjournals.com/international_lexicon_of_aesthetics_item_detail.php?item_id=127

- Getty Conservation Institute. (N.D.). Conservation principles and practice (cleaning and preservation guidance). Retrieved from https://www.getty.edu/conservation/

- ASM International. (N.D.). Materials information on metal oxidation and surface aging. Retrieved from https://www.asminternational.org/

- World CopperSmith. (N.D.). Copper Patina: The 6 Patina Stages. Retrieved from https://www.worldcoppersmith.com/articles/copper-patina/

- Omega Products International. (N.D.). Technical Bulletin: Color Fading in Acrylic Finishes. Retrieved from https://omega-products.com/wp-content/uploads/literature/TechnicalBulletin_Omega_ColorFading.pdf

- Forest Stewardship Council. (N.D.). About FSC and responsible forestry. Retrieved from https://www.fsc.org/

- This Old House. (N.D.). How Heirloom Furniture Is Built. Retrieved from https://www.thisoldhouse.com/furniture/21018437/how-heirloom-furniture-is-built

- Labastille. (N.D.). The Marvel of Metal Patina: Understanding the Process and Beauty. Retrieved from https://labastille.com/the-marvel-of-metal-patina-understanding-the-process-and-beauty/

- Amish Furniture Factory. (N.D.). Heirloom-Quality Furniture: What It Means. Retrieved from https://www.amishfurniturefactory.com/amishblog/heirloom-quality-furniture/

- Sustainability Directory. (N.D.). Heirloom Quality (Emotional Durability). Retrieved from https://lifestyle.sustainability-directory.com/term/heirloom-quality/

- Wagner Meters. (N.D.). 10 Wood Finishes and Their Pros & Cons. Retrieved from https://www.wagnermeters.com/moisture-meters/wood-info/10-wood-finishes/

- Evolve Artisanal. (N.D.). Patina 101: What Is Metal Patina? Retrieved from https://evolveartisanal.com/material/patina-101/

- Fiix Software. (N.D.). Wear and Tear (Glossary). Retrieved from https://fiixsoftware.com/glossary/wear-and-tear/

- Wikipedia. (N.D.). Wear and tear. Retrieved from https://en.wikipedia.org/wiki/Wear_and_tear