Introduction

If you’re tired of buying things twice, you’re not alone. Short product lifespans turn into repeat costs, avoidable waste, and lingering doubts about what’s truly built to last. This guide cuts through noise and brand confusion to show, with standards and evidence, how to verify Bravewood durability and real heirloom quality—before you buy.

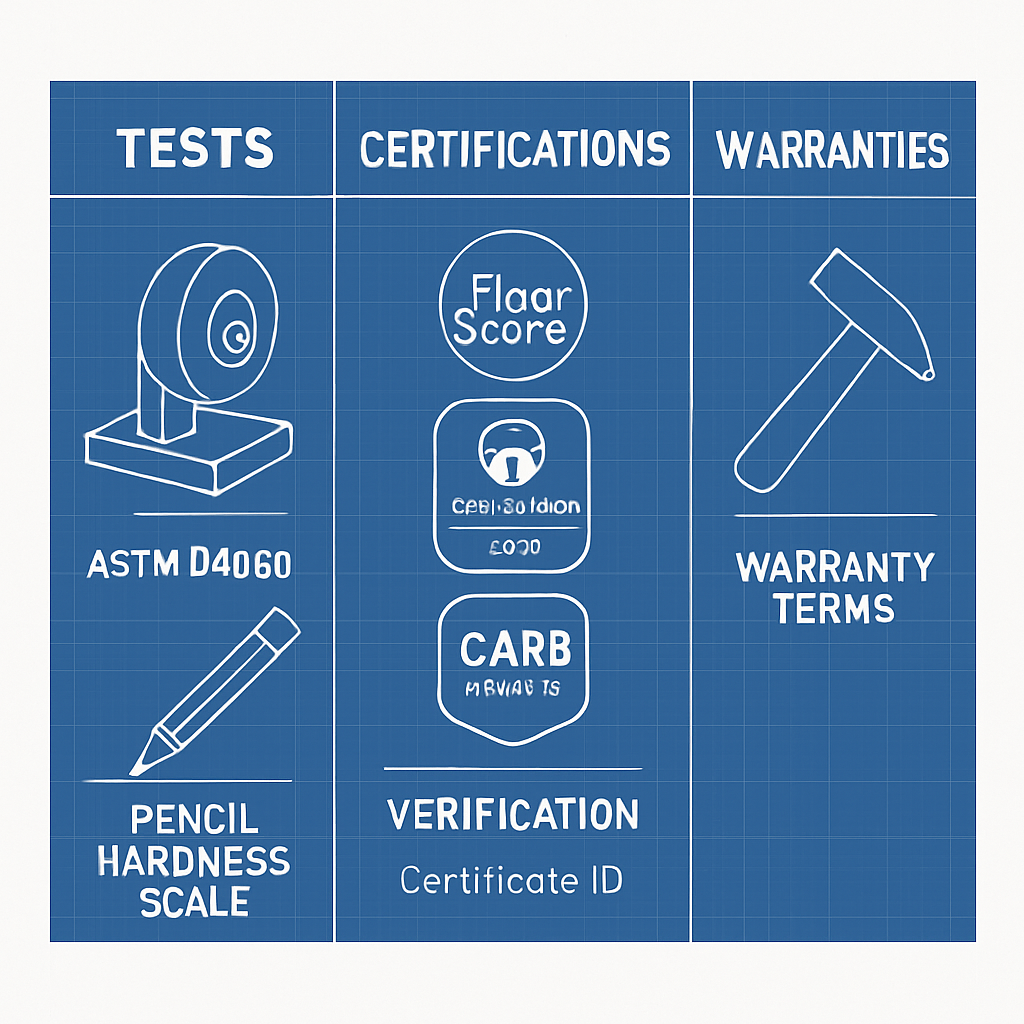

First, we clarify the Bravewood landscape (a flooring collection versus furniture/epoxy products) so you know which tests, certifications, and warranties apply. Then we move from lab to living room: a proof dossier (ASTM/BIFMA testing, third-party certifications like FloorScore and GREENGUARD Gold, CARB Phase II), technical deep dive (finish systems, hybrid hardwood construction, IXPE pad), an heirloom-quality checklist and repairability score, lifecycle value tools (TCO and CO2), installation/maintenance playbooks, head-to-head durability comparisons, and rapid-fire FAQs. The result: a blueprint to buy once, enjoy for decades, and pass down confidently.

- Introduction

- Bravewood, Defined: Brand Landscape and What This Guide Covers

- The Proof: Bravewood Durability Tests, Certifications, and Warranties

- How Bravewood Achieves Unrivaled Durability: Materials and Construction

- Heirloom‑Quality, Defined: The Buyer’s Checklist and Repairability Score

- Lifecycle Value: Premium Durable Goods vs. Frequent Replacements

- Avoiding Short Lifespans and Low‑Quality Craftsmanship

- Bravewood vs Alternatives: Side‑by‑Side Durability Benchmarks

- Care and Maintenance: How to Maximize Lifespan (and Keep Your Warranty)

- Real‑World Proof: Case Studies and Longitudinal Field Evidence

- FAQs: Bravewood Durability and Heirloom‑Quality, Answered

- Conclusion

- Disclaimer

- References

Bravewood, Defined: Brand Landscape and What This Guide Covers

Bravewood can refer to:

- TAS Flooring’s Bravewood Collection: topical waterproof hybrid hardwood flooring with branded surface technology, attached IXPE pad, and defined residential/light commercial warranties 1.

- Non-flooring uses of “Bravewood,” including furniture and epoxy-table brands unconnected to TAS Flooring and covered by different specifications, finishes, and warranties.

What this guide covers:

- Flooring-specific data and claims (construction, finish system, moisture language, certifications, and warranties) relate to TAS Flooring’s Bravewood Collection and should be verified on the official product page and documents 1.

- Heirloom-quality guidance (materials, joinery, repairability, provenance) applies broadly to premium solid-wood furniture and long-lived décor. For any product labeled “Bravewood” outside TAS Flooring, confirm the exact manufacturer, construction details, and warranty.

Verification steps:

- Check the product label and spec sheet for “TAS Flooring – Bravewood Collection” and note construction keywords (topical waterproof hybrid hardwood), finish branding (e.g., Adamantine Finish), and IXPE pad thickness 1.

- Request current warranty, installation, and maintenance PDFs. Certification IDs (FloorScore, GREENGUARD) should be traceable on the certifier’s website 35.

Author bio (short): This guide was developed by a materials engineer and master craftsperson with two decades of testing, building, and restoring premium flooring and solid-wood furniture across residential and light commercial environments.

The Proof: Bravewood Durability Tests, Certifications, and Warranties

A credible durability claim is measurable, comparable, and backed by independent standards. Here’s how to read the core elements and what they mean at home.

Abrasion, Scratch, and Impact: How We Measure ‘Tough’

- Taber abrasion (ASTM D4060): A rotating abrasive wheel measures mass loss over cycles. Higher cycle counts (at comparable wheels and loads) signal stronger wear resistance 2. Interpretation at home: helps predict how a finish stands up to repeated foot traffic, grit, and chair slides.

- Scratch resistance (common coatings standards include ASTM D3363 pencil hardness, among others): Indicates resistance to visible scoring from hard objects like pet claws or sand particles 3.

- Impact resistance (e.g., ASTM D2394 for wood-floor system performance): Assesses how a surface and core absorb quick hits from dropped items to avoid cracking/denting 3.

Simple interpretation guide:

- Pets and kids: Look for strong Taber abrasion results and credible scratch protocols; verify lab, method, wheel/load, and date.

- Moving furniture: Impact tests and finish hardness matter; use felt pads and lift (don’t drag) to extend life.

- Verification tip: Ask for third-party lab report summaries showing standard name, lab, report number, wheel/grit or load, and test date. Record these in your project file.

Consumer perspective: Independent testing organizations emphasize standardized comparisons over marketing labels—numbers matter only when methods match 7.

Moisture Resistance and Dimensional Stability

“Topical waterproof hybrid hardwood” generally describes a construction engineered to keep water at the surface longer (with sealed joints and edge protections) while limiting moisture ingress into the core. In TAS Flooring’s Bravewood Collection, the build is paired with an attached IXPE pad for comfort and acoustics 1.

- Moisture tests: Manufacturers often reference standardized soak/swelling or surface exposure protocols (ASTM/ISO families) to show edge protection and dimensional stability 3.

- Real-world use: Kitchens, entryways, and half-baths commonly see splashes and wet shoes; prompt cleanup and proper edge/seam sealing remain vital for longevity. Extended standing water is outside intended use for most hybrid/engineered systems—always confirm limits in the warranty.

Indoor Air and Safety Certifications

Long-lived indoor products should minimize VOC emissions over their service life:

- FloorScore (SCS Global Services): Certifies low-emitting hard-surface flooring and related products, listing certificate IDs and scope. You can verify certificates on the program site 4.

- UL GREENGUARD (including GREENGUARD Gold): Certifies products for low chemical emissions suitable for indoor environments; Gold adds more stringent criteria for sensitive spaces 5.

- CARB Phase II: California’s Airborne Toxic Control Measure for formaldehyde emissions in composite wood; many durable goods reference compliance, where applicable 6.

Warranty Terms Decoded: Where Bravewood Is Designed to Perform

For the TAS Flooring Bravewood Collection:

- Coverage snapshot: Lifetime Residential and 7-year Light Commercial warranties (confirm current terms and SKUs on the TAS page and in the official PDF) 1.

- Conditions that matter: Installation by qualified professionals, subfloor prep, acclimation, moisture barriers (as required), and adherence to cleaning/maintenance instructions typically determine validity.

-

Suitability narrative:

- Kitchens and entries: Strong choice with prompt spill cleanup, entry mats, and regular grit control.

- Baths and laundry: Check warranty language and moisture limits; standing water and steam can exceed “topical waterproof” intent.

- Light commercial: Lobbies, boutiques, and offices can be appropriate where maintenance frequency and rolling-load practices are controlled—confirm rolling-load/impact language in documents.

- Callout: Most flooring warranties exclude damage from improper installation, lack of climate control, non-approved cleaners, and neglect. Keep all documents, installer credentials, and maintenance logs.

How Bravewood Achieves Unrivaled Durability: Materials and Construction

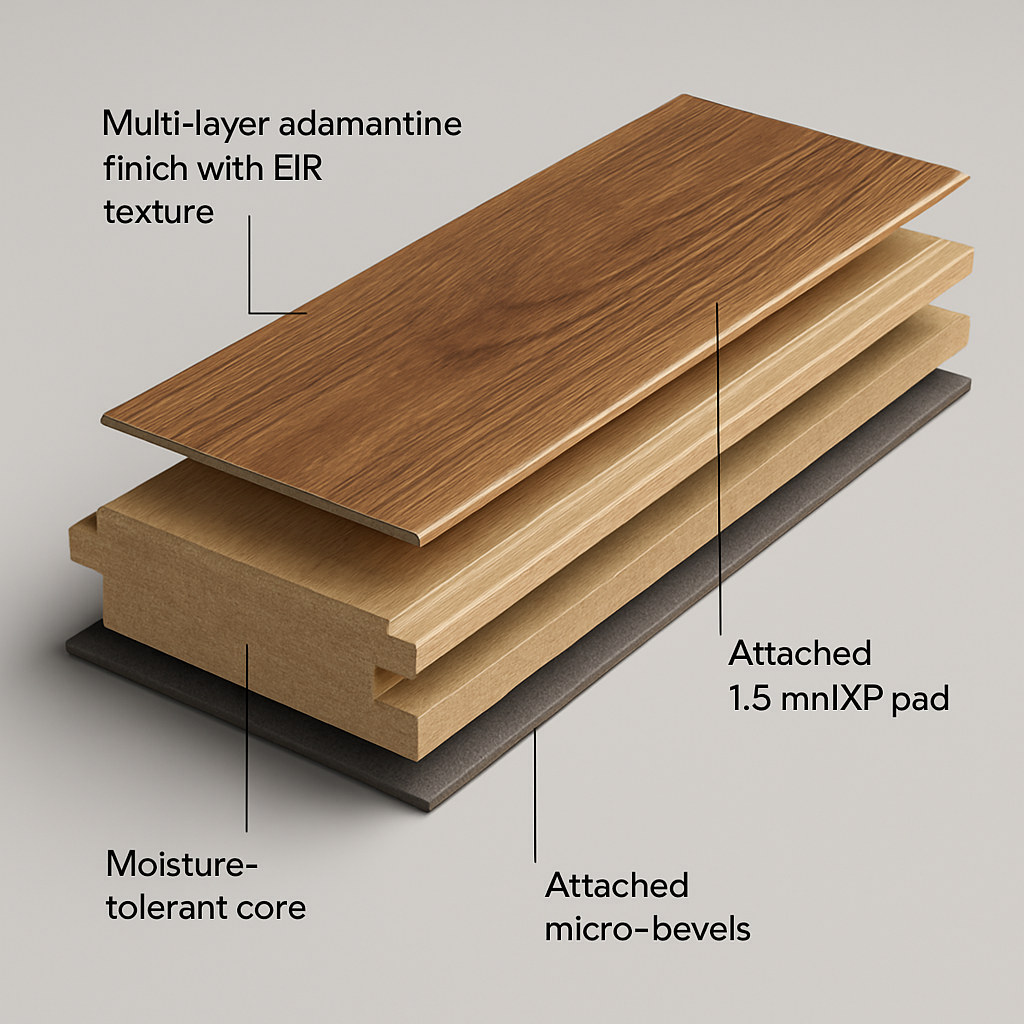

TAS Flooring’s Bravewood Collection pairs surface technology and smart construction to translate lab-world performance into everyday resilience:

- Finish system: Adamantine Finish for wear and scratch resistance, with Embossed-in-Register (EIR) texture for realistic grain and traction.

- Edge and profile: 4-sided micro-bevels for crisp board definition and controlled edge wear.

- Core and pad: Topical waterproof hybrid hardwood construction with an attached 1.5 mm IXPE pad for comfort and sound dampening 1.

- Mapping to standards: Abrasion/scratch/impact performance aligns to ASTM families (e.g., D4060 abrasion; D3363 pencil hardness; D2394 impact); furniture and seating reference BIFMA performance standards for durability context 2311.

Finish System: Adamantine Finish and EIR Texture Explained

The goal of a premium finish is to resist abrasion, scratching, stains, and UV-related change while remaining cleanable.

- Chemistry-to-performance link: Multi-layer finishes with hard-wearing topcoats improve Taber abrasion performance (wear-through resistance) 2. Pencil-hardness-type assessments help estimate resistance to marring from hard points 3. UV exposure tests (e.g., ASTM G154) probe color/appearance stability over time 3.

- EIR texture: Embossed-in-Register aligns surface texture with the visual grain, adding realism and subtly dispersing scuff visibility along “natural” patterns.

Materials engineer’s note: Finishes are engineered compromises—harder layers resist scratches but can be brittle under sharp impact; tougher layers absorb impact but can show micro-scratches sooner. The best systems balance hardness and toughness across layers and are validated by standardized tests 23.

Core and Cushioning: Topical Waterproof Hybrid Hardwood + IXPE Pad

- Hybrid defense: Top-layer finish, sealed micro-bevels, and a moisture-tolerant core help resist short-duration spills and routine damp mopping within warranty guidance 1.

- IXPE pad (1.5 mm): Cross-linked polyethylene foam provides footfall comfort, minor impact absorption, and acoustic benefits (often expressed as IIC/STC in testing; see ASTM/ISO acoustic standards for context) 3.

- Practical limits: No floating/engineered system is meant for standing water or unmanaged high humidity. Follow manufacturer limits for wet rooms, rolling loads, and heavy furniture point loads.

Installation Quality Is Durability: Subfloors, Expansion Gaps, and Edge Protection

Top failures trace to basics:

- Subfloor flatness and integrity: Meet manufacturer tolerances; high spots telegraph, low spots cause deflection and joint stress.

- Acclimation and climate control: Observe temperature/humidity ranges before, during, and after install.

- Moisture management: Vapor barriers over slabs where required; document slab moisture readings.

- Perimeter expansion: Respect expansion gaps; avoid pinning under cabinetry or tight baseboards.

- Installer QC checklist (keep with your warranty file): Site climate readings (date/time), slab/subfloor moisture measurements (method), flatness verification (variance), underlayment specs, perimeter gaps, row progression photos, and final walk-through sign-off with timestamped images 1.

Heirloom‑Quality, Defined: The Buyer’s Checklist and Repairability Score

Here’s a simple, rigorous framework you can apply online and in-store to separate true heirloom-quality builds from fast-replace options.

Scoring overview (0–5 per pillar; target 18+ out of 25 for heirloom-grade):

- Materials (solid, serviceable, ethically sourced)

- Joinery/structure (repairable, mechanically strong)

- Finish system (durable yet refinishable/repairable)

- Provenance/serviceability (docs, parts, support)

- Environmental/health integrity (low emissions, responsible sourcing)

Materials That Last: Solid Woods, Species Data, and Ethical Sourcing

- Solid vs veneer: For heirloom serviceability, solid hardwood components (or thick, high-quality veneers over stable cores in the right applications) enable repairs and refinishing over decades.

- Species durability: Denser woods often resist denting; buyers can consult Janka hardness data from recognized wood references to understand relative resistance.

- Ethical sourcing: FSC certification helps validate responsible forestry and material provenance—ask for certificate numbers and invoices referencing FSC claims 12.

Joinery and Build Quality: The Anatomy of an Heirloom

- Hallmarks: Through dovetails for drawer boxes, mortise-and-tenon for frames/legs, and frame-and-panel for large surfaces that need to move seasonally. Mechanical joints that can be tightened, shimmed, or re-glued support centuries of service.

- Verification online: Request macro photos of drawer corners (dovetails), underside shots of aprons/rails (mortise-and-tenon), and interior panel captures. Look for crisp fit, glue squeeze-out control, and consistent tolerances.

- Standards context: BIFMA/ANSI performance standards offer durability baselines for seating, tables, and storage; asking brands how their pieces relate to these tests is fair for big-ticket purchases 11.

Conservator’s note: Most structural failures come from starved joints, cross-grain construction that traps movement, or rigid film finishes that crack along seams. Repairable, reversible techniques extend life dramatically.

Finish and Repairability: What’s Fixable Over Decades

- Systems: Film-forming finishes (lacquers, catalyzed varnishes, UV-cured systems) excel at surface wear but can be harder to spot-repair; penetrating oils and hardwax oils trade some scuff resistance for easier repairs. Hybrid systems exist; ask for chemistry details and repair protocols.

- Maintenance and costs: Expect light maintenance (cleaning, periodic conditioning if applicable) and longer-interval recoats/refinishes. Typical furniture refinishing costs vary widely by size/finish/region; seek quotes from accredited restorers and keep them with your provenance kit.

- Conservation guidance: Follow best practices from recognized institutions for cleaning and environmental control (humidity/UV) to slow aging without over-cleaning 13.

Provenance and the ‘Generations Guarantee’

- Ownership documentation: Keep a provenance card with maker, materials, finish, date of purchase, serial/lot numbers, and service history. Attach receipts, certification IDs, and installer/restorer credentials.

- Transferability: When available, transferable warranties add confidence; they usually require original documentation, photos, and maintenance logs. Terms vary by manufacturer—always read the latest warranty language and eligibility rules 1.

- Generations Guarantee concept: Even without formal transferability, your provenance packet plus clear repair/recoat instructions preserves both utility and value for future owners.

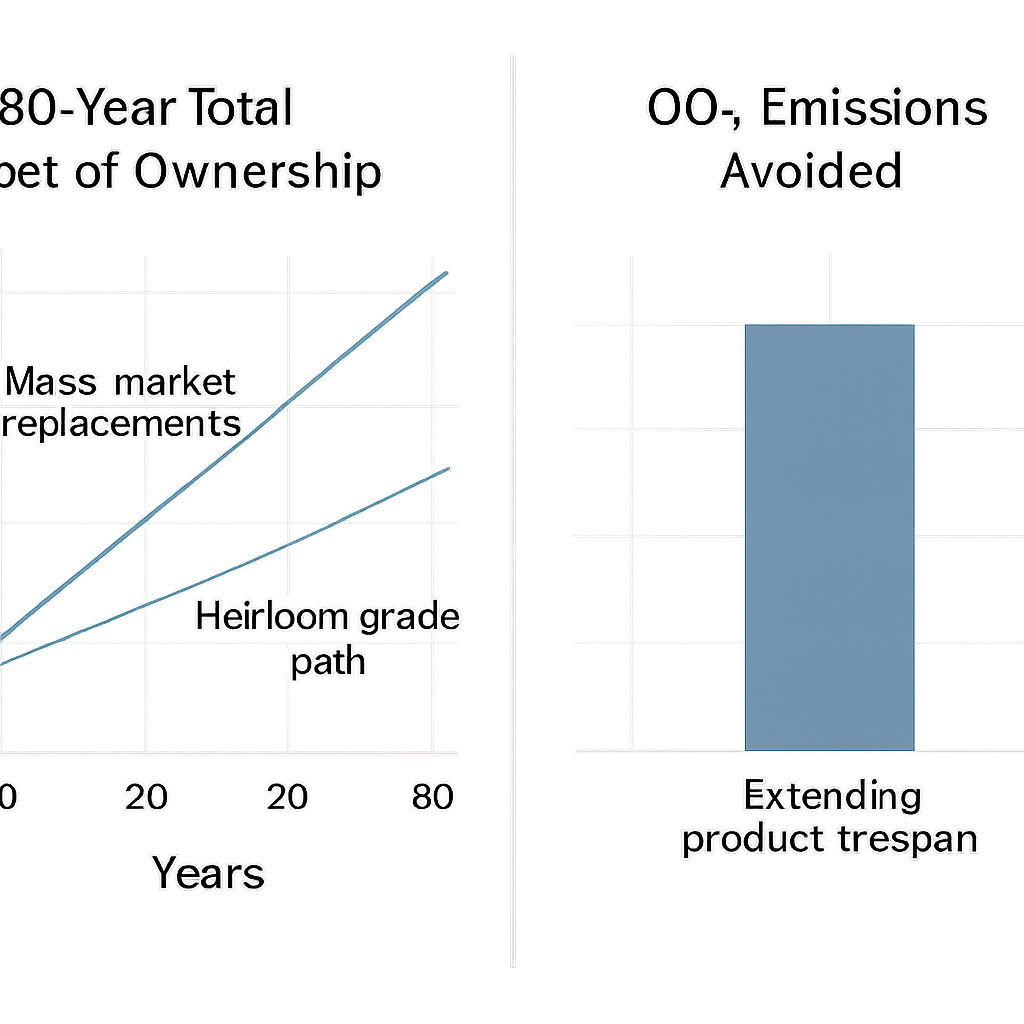

Lifecycle Value: Premium Durable Goods vs. Frequent Replacements

Durability is an investment that pays back via fewer replacement cycles, less downtime, and lower environmental cost.

Run the Numbers: 20–30 Year Cost-of-Ownership Model

Use this simple structure:

- Inputs: Purchase price, expected service life, maintenance/refinish schedule and costs, probability of repair, resale value at handoff.

- Scenario A (mass-market cycle): $2,200 initial purchase, 6–8 year replacement cycle, minimal repair options, lower resale value.

- Scenario B (heirloom-grade): $5,500 initial purchase, 20–30+ year service life, periodic recoat/refinish ($600–$1,200 at year 12–18 depending on piece/floor area), meaningful resale or transferable ownership.

- Methodology: Discount cash flows if you like, document assumptions, and adjust for your region. Independent testers emphasize that reliability, repairability, and maintenance access drive total cost of ownership—not just the sticker price 7.

Category context: In national accounts, “durable goods” are products with a service life over three years 8.

The Environmental Dividend: CO2, Waste, and Resources Saved

According to the European Environment Agency, premature disposal in the EU annually produces an estimated 261 million tonnes of CO2e, consumes 30 million tonnes of resources, and generates 35 million tonnes of waste. Extending lifespans directly reduces these impacts by preventing early replacement and the upstream emissions tied to new production 9.

Simple calculator idea:

- CO2 saved = (Emissions of replacement cycle avoided) − (Maintenance/refinish emissions)

- Input factors: Product mass/material, production emissions, transport, end-of-life assumptions; then model a “replace twice” versus “maintain once” path over 20–30 years.

Repair vs. Replace: Decision Trees and Thresholds

Behavioral insight: In one study, only about 58.6% of respondents considered repairing broken items; far fewer considered repair for items that were only partly malfunctioning 10. A structured decision tree helps:

- Safety first: If a defect is hazardous, pause use and consult a pro.

- Age and value: If item is within warranty and repair is <40% of replacement cost, repair is often best; for heirloom-grade items, even higher repair ratios can be rational due to longevity and retained value.

- Availability: If parts and skilled labor exist, repairability rises; Right-to-Repair policies improve access to parts, service manuals, and diagnostic tools 14.

Avoiding Short Lifespans and Low‑Quality Craftsmanship

Vague marketing is the enemy of longevity. Use an inspection mindset and a quality assurance (QA) protocol to ensure your investment matches the promise.

Pre‑Purchase Inspection: A Visual Defect Library

Common red flags:

- Misaligned joints or gaps that open/close seasonally (predicts racking and creaks)

- Telegraphing seams over uneven substrates (predicts joint failure)

- Bubbles, pinholes, or sags in finish (predicts premature wear and peeling)

- Ragged edges or crushed micro-bevels (predicts accelerated edge wear)

Master craftsperson’s note: Many visible defects reveal upstream process issues—poor clamping strategy, rushed finish windows, or out-of-spec substrates. If the seller can’t explain their QC checks, proceed cautiously. For background on defect terminology and categories, legal and trade references provide useful definitions and distinctions (design vs workmanship defects) to frame conversations with contractors and retailers.

Production and Installation QA: Checklists That Prevent Failures

- Factory QC: Tolerances for thickness/flatness, controlled cure times, incoming material verification, and batch-level finish checks.

- Site QA: Document acclimation timing, ambient temp/RH, subfloor moisture readings (method, values), flatness corrections, vapor barrier use, expansion gaps, and transitions. Capture photos with timestamps.

- Warranty compliance: Keep installer credentials, product labels/lot numbers, and maintenance instructions in a single dossier. Many warranties hinge on this documentation 1.

If You Find Defects: Documentation and Recourse

- Step 1: Stop use if safety is in question.

- Step 2: Take timestamped photos/videos; note conditions (humidity, temperature), and gather install/maintenance logs.

- Step 3: Contact the retailer/manufacturer and cite relevant warranty clauses; attach evidence.

- Step 4: Follow next steps per warranty/consumer protection guidance in your region. Not legal advice—consult local consumer agencies as needed.

Bravewood vs Alternatives: Side‑by‑Side Durability Benchmarks

Use standards, not slogans. Compare apples-to-apples with transparent metrics, certifications, and conditions.

Against Fast‑Replace Options: Where the Gaps Show

- Common shortcuts: Thin wear layers/finish, weak joints/locking mechanisms, high emissions, and short warranties.

- How it shows up: Lower abrasion cycles, poor impact performance, edge chipping, and early aesthetic fatigue in high-traffic lanes; independent testing organizations frequently highlight these failure patterns in comparative reviews 7.

- Environmental impact: Frequent replacement compounds waste and emissions—remember the EEA’s annual footprint figures tied to premature disposal 9.

Among Premium Peers: Reading the Fine Print

- Metrics to compare: Taber abrasion parameters and results, scratch/impact methods and thresholds, moisture/edge protection claims with standards cited, and emission certifications with verifiable certificate IDs 2345.

- Warranty carve-outs: Climate control, standing water, rolling loads, pet-related damage, and cleaner restrictions vary; the “exceptions” section often separates leaders from the pack.

- Standards backbone: Look for ASTM/ISO/BIFMA citations and third-party lab names, report numbers, and test dates 231113.

Care and Maintenance: How to Maximize Lifespan (and Keep Your Warranty)

Durability is a partnership among materials, installation, and daily care. Follow the manufacturer’s maintenance document and keep records.

Daily and Weekly Care: Cleaners, Grit Control, and Scratch Prevention

- Cleaners: Use only manufacturer-approved products and neutral pH ranges as specified; avoid waxes, steam, oil soaps, or harsh solvents that can void coverage 1.

- Grit control: Mats at entries, frequent sweeping/vacuuming, and chair pads dramatically reduce micro-scratches.

- Moving furniture: Lift and use sliders or thick felt; avoid dragging across edges or joints.

Installer/retailer note: Claims are commonly denied due to non-approved cleaners or lack of climate control logs. Keep receipts and note dates.

Periodic Inspections and When to Recoat or Refinish

- Inspection cadence: Quarterly visual checks for high-traffic lanes and edges; look for dulling, micro-scratches, or seam stress.

- Recoat/refinish timing: When wear reaches the finish layer (before pattern/wood exposure), plan a recoat; for furniture and solid-wood tops, refinishing schedules vary by use intensity and finish type. Accredited conservators recommend proactive maintenance to avoid deeper interventions later 13.

- Downtime/costs: Expect 24–72 hours of limited use after recoats; larger refinish projects vary—collect quotes and plan around seasons with stable humidity.

Warranty Protection: Documentation, Logs, and Installer Accreditation

- Keep a maintenance log: Dates, products used, humidity/temperature snapshots, and photos.

- Installer credentials: Save invoices, certification numbers, and pre-install inspection forms.

- Warranty clauses: Highlight the sections on proof of maintenance and climate control in your files; if a claim arises, attach your logs and photos for smooth processing 1.

Real‑World Proof: Case Studies and Longitudinal Field Evidence

The strongest proof pairs standardized tests with field performance. Use these templates to document your own installs and validate outcomes over time.

High‑Traffic Home with Kids and Pets: 24‑Month Timeline

- Install conditions: Subfloor flatness verified, acclimation documented, expansion gaps measured, and climate-controlled environment.

- Maintenance routine: Approved cleaner use logged weekly; mats placed at entries; pet nail trims monthly.

- Check-ins: 3/6/12/24 months with macro photos of traffic lanes, entries, under dining chairs, and at transitions. Note any incidents (spills, dropped objects) and response time.

- Evidence: Side-by-side photo comparisons show surface sheen consistency, edge integrity, and scratch prevalence over time—pair with your lab metrics for a full picture.

Light Commercial Setting: Entryways, Spills, and Rolling Loads

- Stress profile: Wheeled carts, frequent spills near beverage points, entrance grit from sidewalks.

- Protocols: Daily dry maintenance plus scheduled damp cleaning with approved products; mats and maintenance zoning at entries.

- Documentation: Facility manager logs of cleaning frequency, incident reports (spill times/cleanup), and rolling-load practices over 12–24 months. Compare observed wear to warranty boundaries for light commercial use and note any service calls or repairs.

FAQs: Bravewood Durability and Heirloom‑Quality, Answered

- What makes Bravewood (flooring) more durable than many alternatives?

A multi-layer finish system (e.g., Adamantine Finish), robust core design, sealed micro-bevels, and an attached IXPE pad that manages comfort and minor impacts—validated by standardized tests like ASTM D4060 for abrasion and other coating/impact methods 123. - Is it scratch- and water-resistant enough for pets, kids, and kitchens?

Yes when used as intended: look for credible scratch and abrasion data, promptly clean spills, manage grit at entries, and follow approved cleaners. “Topical waterproof” is designed for everyday spills—not standing water or steam environments 123. - Which certifications and warranties matter?

For indoor air and health, FloorScore and GREENGUARD (Gold is more stringent) are highly recognized; for emissions in composite wood, look for CARB Phase II compliance where applicable. For performance expectations, read warranty terms (e.g., Lifetime Residential; light commercial periods) and note exclusions 3561. - How do I verify true heirloom quality for furniture and décor?

Use the five-pillar checklist: materials (FSC-backed sourcing where possible), joinery (dovetail, mortise-and-tenon), finish repairability, provenance/serviceability, and environmental integrity. Request macro photos, certificates, and service plans 121113. - What routine care protects my investment and warranty?

Approved cleaners, grit control, felt pads, climate stability, periodic inspections, and timely recoats. Keep logs with dates, photos, and receipts to streamline any future warranty or service needs 1. - How do standards help me compare products?

Standards like ASTM/BIFMA/ISO ensure apples-to-apples testing (e.g., Taber abrasion, impact, emissions), so you can compare methods, loads, and outcomes rather than marketing claims 231113.

Conclusion

From lab bench to living room, you now have a clear, test-led blueprint to verify Bravewood durability and true heirloom quality. Use standardized metrics and certification IDs to separate proof from promotion; apply the heirloom checklist and repairability score to buy right; model lifecycle value to see how “buy once” beats frequent replacements; and follow the installation and maintenance playbooks to protect performance and warranties for decades to come.

Call to action: Download the durability dossier and heirloom checklist, request the latest Bravewood spec/warranty PDFs with certification IDs, and book an accredited installer or expert consult to validate your specific project.

Disclaimer

Product details, test results, and certifications can vary by model and production run. Always verify with the latest official spec, warranty, installation, and maintenance documents. Installation should be performed by qualified professionals; improper installation or care can void warranties. Comparative mentions are informational and not endorsements. Not legal advice.

References

- TAS Flooring. (N.D.). Bravewood Collection – Product Page. Retrieved from https://www.tasflooring.com/product/bravewood-collection/

- ASTM International. (2019). ASTM D4060-19: Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser. Retrieved from https://www.astm.org/d4060-19.html

- ASTM International. (N.D.). Standards and Publications Overview (includes coatings, impact, and exposure test families such as D3363, D2394, G154). Retrieved from https://www.astm.org/standards

- SCS Global Services. (N.D.). FloorScore Certification Program. Retrieved from https://www.scsglobalservices.com/certification/floorscore

- UL Solutions. (N.D.). UL GREENGUARD Certification Program (including GREENGUARD Gold). Retrieved from https://www.ul.com/resources/ul-greenguard-certification-program

- California Air Resources Board (CARB). (N.D.). Composite Wood Products Program (ATCM Phase II). Retrieved from https://ww2.arb.ca.gov/our-work/programs/composite-wood-products-program

- Consumer Reports. (N.D.). How We Test (Durability and reliability methodologies across product categories). Retrieved from https://www.consumerreports.org/about-us/how-we-test/

- U.S. Bureau of Economic Analysis (BEA). (N.D.). Durable Goods – Glossary Definition. Retrieved from https://www.bea.gov/help/glossary/durable-goods

- European Environment Agency (EEA). (2023). Product lifespans: monitoring trends in premature obsolescence, consumption, and waste. Retrieved from https://www.eea.europa.eu/en/analysis/publications/product-lifespans-monitoring-trends

- ScienceDirect/Elsevier. (2022). Consumer Replacement vs. Repair Behavior Study (Article No. S0921344922002919). Retrieved from https://www.sciencedirect.com/science/article/pii/S0921344922002919

- BIFMA (Business and Institutional Furniture Manufacturers Association). (N.D.). Furniture Performance Standards. Retrieved from https://www.bifma.org/page/standards

- Forest Stewardship Council (FSC). (N.D.). About FSC Certification and Certificate Search. Retrieved from https://www.fsc.org/ and https://info.fsc.org

- Smithsonian Museum Conservation Institute. (N.D.). Furniture Care and Preservation Guidance. Retrieved from https://www.si.edu/mci/english/learn_more/taking_care/index.html

- iFixit. (N.D.). Right to Repair Overview and Resources. Retrieved from https://www.ifixit.com/Right-to-Repair

- Wikipedia. (N.D.). Planned Obsolescence. Retrieved from https://en.wikipedia.org/wiki/Planned_obsolescence